The post ANSI/AAMI ST108 Summary: Water for the Processing of Medical Devices appeared first on ChemTreat, Inc..

]]>ANSI/AAMI ST108 Water for the processing of medical devices was approved on August 16, 2023. This standard replaced the Technical Information Report 34. Unlike the Technical Information Report, the updated standard provides clear requirements for every stage of medical device processing. ANSI/AAMI ST108 establishes minimum requirements for water quality and steam purity for processing medical devices intended for patient use. Proper implementation of this standard improves the effectiveness and lifespan of equipment, such as ultrasonic sterilizers, endoscope reprocessors, autoclaves, and local steam generators. Implementing this standard involves a comprehensive process, starting with an assessment of current water quality management practices.

Standard Applicability

The applicability of ANSI/AAMI ST108 applies to facilities that have medical device processing equipment (cleaning, rinsing, disinfection, and sterilization). Criteria includes the considerations listed below.

Water is categorized into three different types based on the disinfection characteristics or sterilization process type.

a. Utility water is tap water that is used for rinsing, flushing, and intermediate rinsing (rinsing between cleaning and disinfection). This water may require treatment.

b. Critical water is final rinse water that has been processed by highlevel disinfection. To meet the water quality requirements, critical water requires an extensive multi-step treatment process. This process can include pretreatment, storage, distribution, and final treatment.

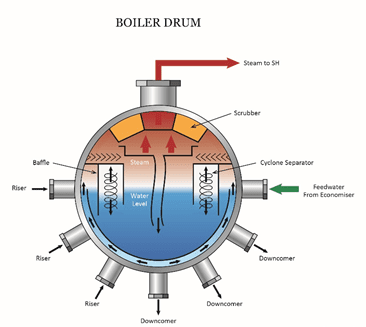

c. Steam is considered vaporized water produced by a centralized boiler near the sterilizer(s). Steam is tested as condensate, following the sterilizer.

A multidisciplinary team must be established and should have knowledge of the water systems and associated processes in use. Team members should include facilities engineering staff, infection prevention, medical device processing personnel, clinical engineering staff, and water treatment specialists.

A risk analysis should be performed to evaluate and identify risks associated with utility water, critical water, and steam. The following water characteristics should be considered: physical appearance, microbial concentrations, inorganic/organic contaminants, pH, conductivity, and temperature.

Routine monitoring and performance qualification testing is essential to maintaining the integrity of the water treatment systems. The updated standard provides detailed guidance on water quality testing standards, testing frequency, and system functionality. Monitoring is performed by the multidisciplinary team. The team reviews the water quality results and implements the necessary corrective actions if the results are out of range. The standard includes reference tables that specify testing parameters and frequencies.

The new standard provides guidance on water treatment system installation, operation qualification, and design of water treatment systems. It also provides recommendations on service interruptions, system shutdowns, and construction related activities.

The standard serves as a framework for facilities to create an impact on water quality and patient safety. Proper implementation of this standard can help prevent issues such as, medical device and processing equipment damage, processing inefficiencies, and negative patient outcomes from surgical site infections.

To access the standard, go to: https://www.aami.org

Download the PDFThe post ANSI/AAMI ST108 Summary: Water for the Processing of Medical Devices appeared first on ChemTreat, Inc..

]]>The post Direct-to-Chip Liquid Cooling Treatment Helps DOE National Laboratory Improve System Performance appeared first on ChemTreat, Inc..

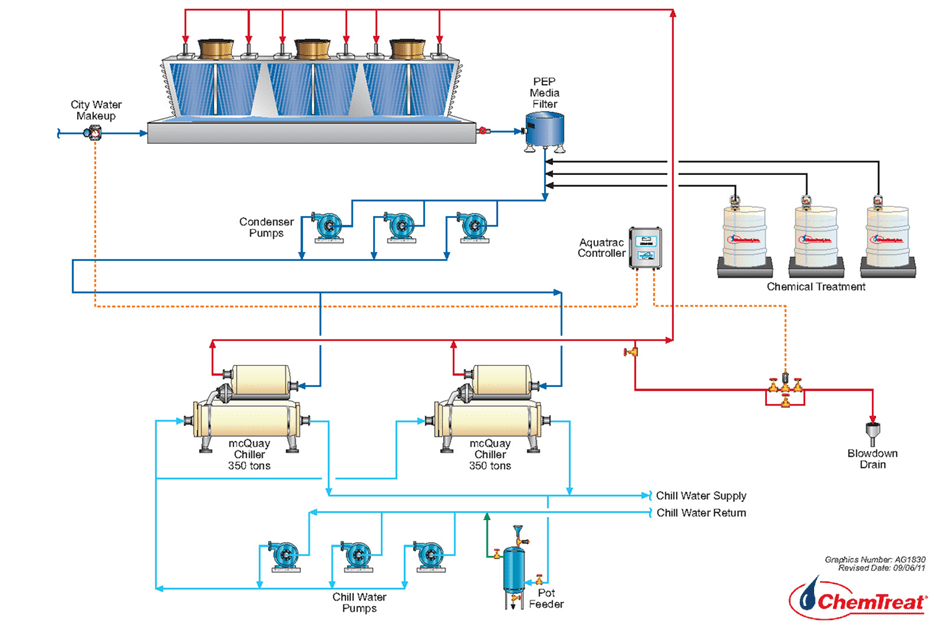

]]>National laboratories managed by the Department of Energy (DOE) often have extensive direct-to-chip liquid cooling and high-performance computing (HPC) systems that need to operate at peak efficiency to meet critical research goals. These facilities require a variety of customized water treatment solutions to maintain operating efficiency and preserve their assets.

One national laboratory in the Southern United States was struggling with performance issues in its open recirculating, closed loop, and HPC cooling systems. As a preferred water treatment consultant to the DOE, ChemTreat employed state-of-the-art technologies and provided technical and analytical support to address the lab’s needs.

Improving Cooling System Performance

Addressing Inefficiencies in Open Recirculating Cooling Towers

Project Description

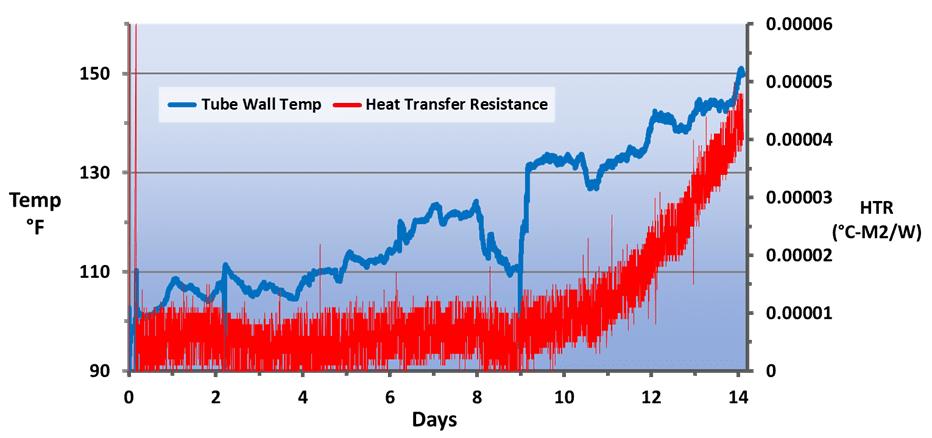

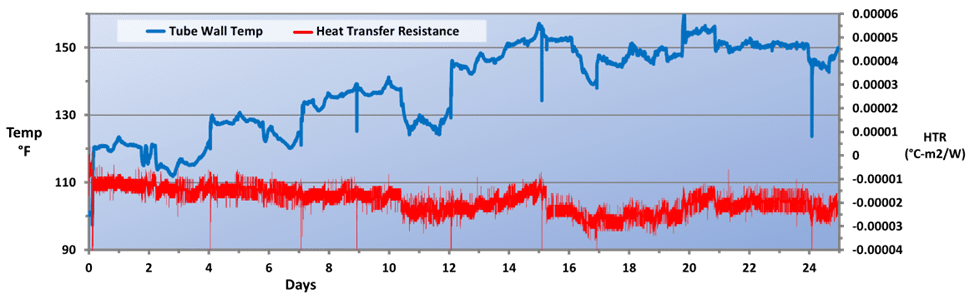

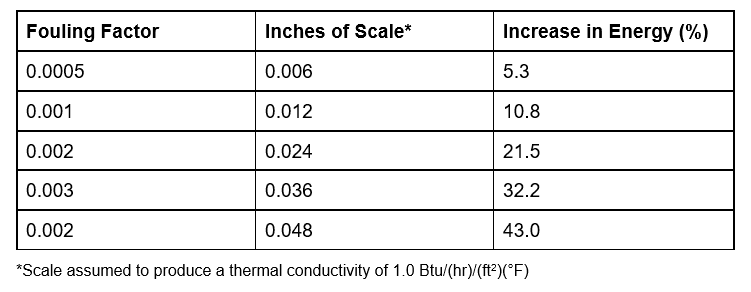

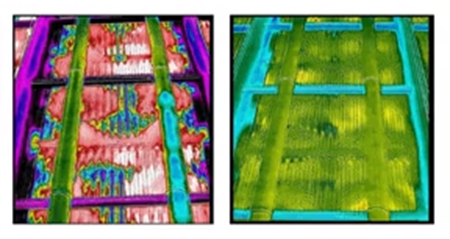

The laboratory operates several large open recirculating water systems responsible for cooling critical research equipment and data center HPCs. These systems were fouled with mineral deposits that significantly impacted heat transfer and cooling efficiencies and contributed to increased metal corrosion and microbiological activity.

Solution

To address these issues, ChemTreat’s Research & Development team developed a treatment solution using Quadrasperse® polymeric dispersant and corrosion inhibition technologies, specifically designed to meet the unique needs of this facility.

Results

After applying our custom-designed treatment program, mineral deposits were removed from the cooling tower fill and heat exchanger surfaces, significantly improving heat transfer efficiency and reducing the risk of underdeposit corrosion and microbiological activity.

Enhancing HPC Cooling Performance

Project Description

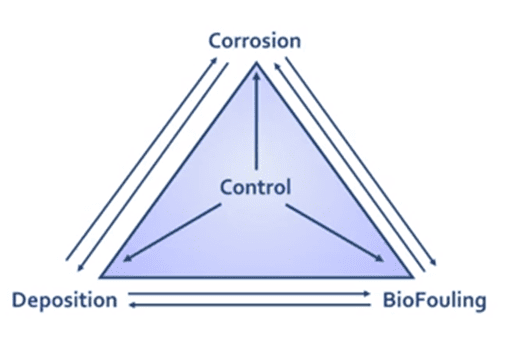

The facility has many computer applications with direct-to-chip liquid cooling, including a large, recently built HPC that was unable to pass speed testing because of poor cooling performance.

The HPC’s cooling loops had become heavily fouled with biological growth, mineral scale, and other additives, preventing the unit from reaching the maximum expected calculations per second that it was designed to achieve.

Traditional cooling treatment methods add film inhibitors, such as silicates, to control corrosion, and biocides to mitigate microbiological issues. However, direct-to-chip liquid cooling systems have slightly different needs.

Solution

ChemTreat developed CL2001, a product specifically designed for CPU applications, to treat the laboratory’s HPC cooling loops. This treatment methodology takes a more holistic approach, avoiding inhibitors that can cause fouling while implementing a proprietary protocol to control corrosion and microbiological activity.

Results

The CPU cooling at the site has been optimized with CL2001 treatment, and the HPC has passed the speed test. Stress testing is ongoing, and the laboratory is expected to accept ownership of the HPC from the manufacturer in the coming months.

Addressing Fouling and Corrosion in Aluminum Closed Loop Cooling Systems

Project Description

The closed loop system was experiencing fouling events that led to underdeposit corrosion in aluminum equipment, reducing heat transfer efficiency.

Solution

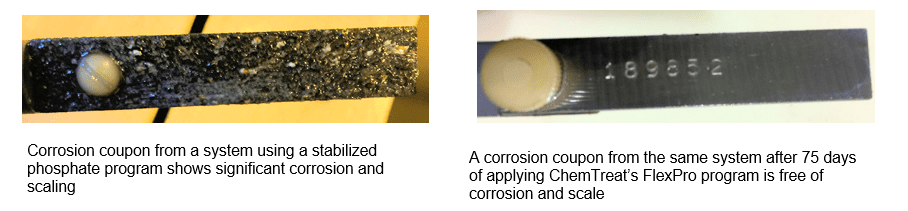

The facility began using ChemTreat’s patented FlexPro® multi-metal corrosion inhibitor specifically designed for aluminum applications. The new inhibitor has a neutral pH, allowing the cooling systems to operate within an acceptable pH range.

Results

Thanks to the application of the patented FlexPro corrosion inhibitor, the chilled water loop is now free from suspended solids caused by corrosion byproducts. The water clarity is excellent, and heat transfer and cooling efficiency have improved greatly. Aluminum corrosion has been reduced from >10 mpy to <0.1 mpy.

Value-Added Water Conservation Project

In addition to treating the issues experienced by the laboratory’s closed loop cooling systems, ChemTreat implemented a program to help the facility meet environmental goals.

Utilizing a proprietary, state-of-the-art aluminum corrosion inhibitor, ChemTreat assisted the laboratory with a once-through to closed loop cooling water conservation project, saving 34 million gallons of water per year while protecting critical research equipment.

Conclusion

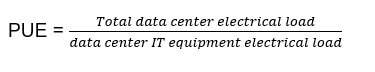

ChemTreat’s water treatment expertise and custom solutions helped a national laboratory improve the efficiency of its direct-to-chip liquid cooling and other cooling systems.

The results of this partnership have yielded the following benefits for the facility:

- Cooling tower systems have remained free of mineral deposits and have exhibited excellent corrosion and microbiological control for more than a decade.

- Improvements to CPU cooling treatment helped the facility’s HPC pass the speed test.

- Aluminum corrosion reduction in the closed loop improved water quality and heat transfer efficiency.

- A water conservation project in the closed loop cooling system helped the laboratory save 34 million gallons of water annually.

Results are examples only. They are not guaranteed. Actual results may vary.

The post Direct-to-Chip Liquid Cooling Treatment Helps DOE National Laboratory Improve System Performance appeared first on ChemTreat, Inc..

]]>The post RO Makeup Water Sources: Addressing Variable Water Quality to Maintain System Efficiency appeared first on ChemTreat, Inc..

]]>This article discusses the characteristics of various makeup sources and outlines processes for analyzing RO makeup water.

Read on to:

- Examine the various types of makeup water sources.

- Explore the impact of minerals, organics, microbiological growth, and other constituents on RO systems.

- Learn some best practices for maintaining RO system efficiency.

Makeup Water Sources: Where is the Water Coming From?

To understand the potential vulnerabilities of an RO system, it is important to know its makeup water source.

RO manufacturers typically suggest cleaning systems every 3–4 months; yet, in many cases, RO systems require more frequent cleanings. This is, in part, because of the differences in water coming from varying makeup sources, and more importantly, the performance of the upstream filtration equipment. Pretreatment is a key component of reliable and efficient RO.

Makeup water quality is very important. Any imperfections in the water can lead to fouling, scaling, and corrosion if not treated properly.

Surface Water

Surface water is drawn from sources such as:

- Rivers

- Lakes

- Reservoirs

- Canals

Typically, all surface waters contain fluctuating levels of suspended and colloidal particles, organics, microbiological activity, and turbidity. If the makeup source is a river, for example, the clarity or turbidity will change based on rainfall and land runoff.

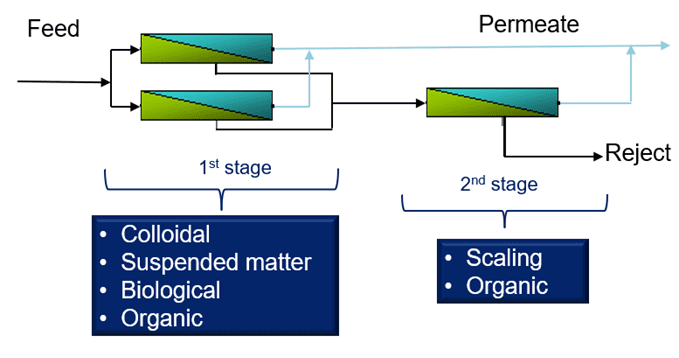

Surface water contains suspended and colloidal particles, which will pass through a 5-micron cartridge filter in the RO, increasing pressure changes (ΔP). This can result in RO fouling during the first stage. Conducting a Particle Size Analysis of the makeup water and the outlet of the cartridge filter housing is recommended at this stage.

Well Water

Another source for makeup is well water.

- Shallow wells are typically located anywhere from 40 to 150 feet below the surface.

- Deep wells can be found anywhere from 600 to 1,000 feet below the surface.

Generally, the deeper the well, the cleaner the water. Deep wells have more consistent temperatures, and water pulled from these wells often contains lower levels of bacteria, colloidals, organics, and suspended particles.

Gray Water

Gray water typically refers to tertiary wastewater intended for municipal and industrial reuse.

In recent years, water scarcity has made gray water a more popular source for makeup. Instead of using surface water, many municipalities now use gray water from power plants, chemical plants, and refineries for their processes.

Although gray water use has gained in popularity, it comes with unique treatment challenges. Gray water typically has a large amount of organic loading, ammonia, and phosphates, while its low chlorine residual is rarely sufficient for removing microbio.

How to Maintain RO Efficiency with Makeup Water Analysis

Silt density index (SDI) testing is a best practice for analyzing RO makeup, as it measures the fouling capacity of the water used in the RO.

SDI testing is performed on site with an SDI kit. The test requires a constant makeup stream at 30 psi. This stream is passed through a 0.45-micron filter pad at a known volume for 15 minutes to calculate SDI.

Typically, RO manufacturers recommend an SDI of 5 or below, but many are now indicating that 3 or less is needed for good RO performance.

In most cases, the lower the SDI, the better the system will run. It is a good idea to save the SDI pads for historical reference.

Upstream Chemical Addition to Surface Water Makeup

Utilizing surface water as a makeup source requires facilities to implement either a clarification process to remove turbidity or a cold lime softening process to reduce hardness, alkalinity, and turbidity.

Regardless of which process is implemented, treatment will include coagulant and/or flocculant chemicals.

Coagulants

Coagulants have one of three bases:

- Aluminum

- Iron

- Organic

The amount of coagulant fed to the system greatly varies based on the surface water source.

A good example of this is the Mississippi River, which flows north to south. At the top of the river in Minnesota, the turbidity level of the water is low, so coagulant feed will be in a low parts per million (ppm) range.

As it moves south, the Mississippi meets the Missouri, Illinois, and Ohio rivers. These confluences lead to turbidity formation, so water treatment plants along the river feed higher amounts of coagulant into their system to adjust for higher turbidity.

Flocculants

Flocculants also play an important role in turbidity reduction. They can be cationic, anionic, or non-ionically charged. Flocculants are typically dosed at less than 2 ppm, so it is important to monitor how flocculants are being added to your system.

The Challenges of Coagulant and Flocculant Treatment

Though coagulants and flocculants are beneficial for producing the desired finished water quality, they can still be detrimental to overall RO membrane health.

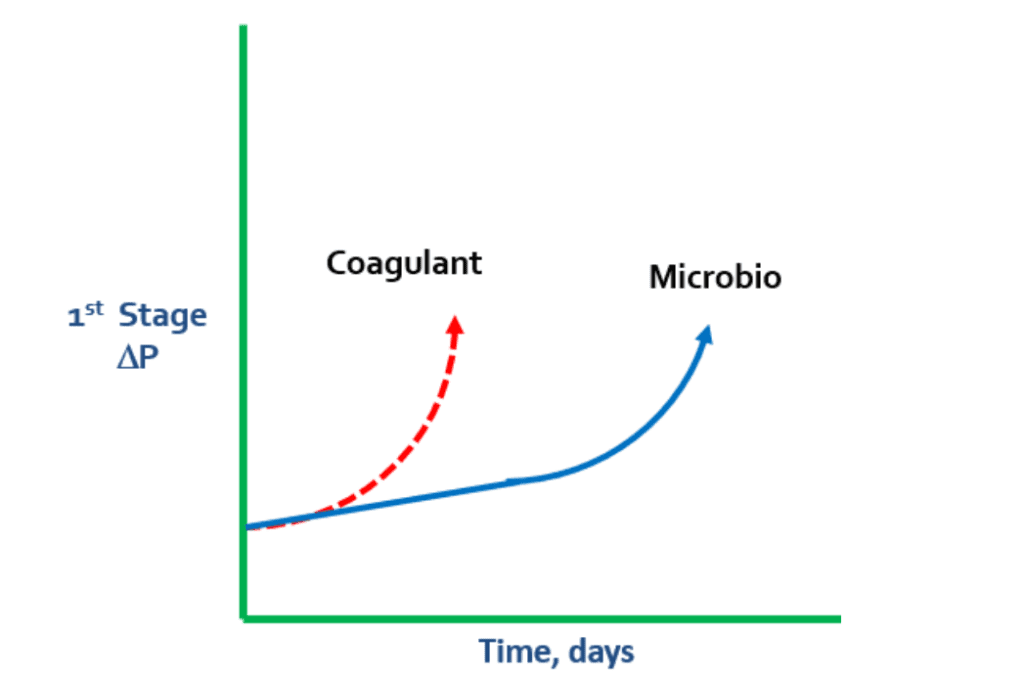

Unlike the slightly negatively charged RO membranes, coagulants are cationically charged, which can cause pressure changes. If there is a rapid spike in ΔP during the first stage, it is prudent to look for a coagulant problem. Coagulant levels may not have been adjusted to match changes in turbidity, which can result in coagulant overfeed.

In these cases, coagulant begins to lay down on the membrane and grab microbio, particles, and colloidals. When the negatively charged bacteria meets the positively charged coagulant, the coagulant continues to grab more and more microbio.

In some cases, extreme levels of polysaccharides in microbio can cause a “flypaper” effect, which leads to microbiological matter grabbing suspended solids and colloidals from the water. This can result in membrane fouling.

If the RO membrane is not cleaned properly, coagulant issues can lead to gap formation.

Once gaps form inside an RO membrane, they are very difficult to remove. Therefore, it is important to monitor microbio levels within the makeup water as it enters the system.

Additionally, if a plant is using city water for makeup, it is recommended that facility personnel contact the municipality and ask what type of coagulant has been used upstream.

The Impact of Minerals on Makeup Water

It is also important to be aware of the mineral contents of makeup water.

Minerals can be broken down into two separate subgroups: cations and anions.

Examples of each are included below:

| Cations | Anions |

|---|---|

| Calcium | Total Alkalinity |

| Magnesium | Chlorides |

| Sodium | Sulfates |

| Potassium | Nitrates |

| Barium | Fluoride |

| Strontium | Orthophosphate |

| Aluminum | Silica |

| Iron | |

| Manganese |

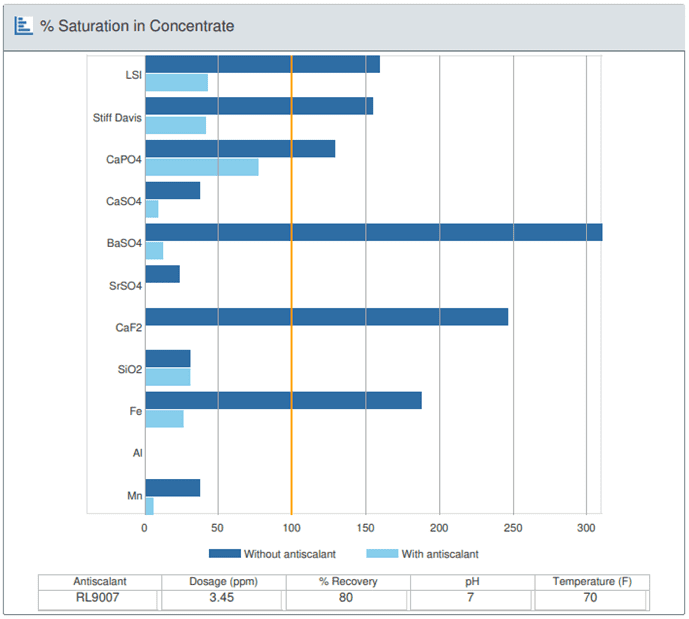

Testing makeup water for mineral content is an essential step in determining the type of RO antiscalant to use and the percent RO recovery rate.

Of the cations, barium, aluminum, iron, and manganese are particularly important to monitor. Levels of each should typically not exceed 0.05 ppm (50 ppb).

Aluminum can be especially problematic. It is typically fed as a coagulant to reduce turbidity, but excess aluminum can lead to RO fouling, which can be difficult to treat with an antiscalant.

The following anions: total alkalinity, orthophosphate, fluoride, and silica, may also need to be monitored closely. Gray water is particularly prone to supplying excess phosphates.

The recommended testing frequency for minerals in makeup is:

- Every other month for surface water sources

- Quarterly for well water

- Monthly for gray water

In general, calcium phosphate, calcium sulfate, and barium sulfate can all be treated with an antiscalant, while aluminum, iron, and manganese may be a bit more difficult treat.

Other Important Testing Parameters

pH

Once the pH and total alkalinity are known, the amount of free carbon dioxide (CO2) can be calculated.

Because it is a gas, CO2 passes through the RO membrane, which can lead to pH reduction in the permeate.

Since CO2 is not detected by a conductivity meter, it can flow downstream to the mixed bed and result in a large amount of hidden loading. This could require more frequent replacement of the mixed bed.

Conductivity

Calculating conductivity provides an idea of the number of ions present in the water. For example, high conductivity (300–500 µS) may indicate that hardness and alkalinity levels are within range, but there may still be a high number of chlorides or sulfates in the water. High conductivity may also suggest that more permeate is traveling downstream to the softener or other ion exchange unit.

Total Organic Carbon (Organics)

Surface waters are notorious for having high levels of organic matter, which is measured as total organic carbon (TOC). For RO feedwater, the TOC limit is 3 ppm.

- TOC can be natural or synthetic:

- Natural organics

- Tannin, Lignin, Humic, etc.

- Typically yellowish to brownish in color

- Great source of nutrients for bacteria

- Synthetic organics

- Often coming from farm runoff chemicals

- Can have a greater fouling effect on RO membranes compared to natural organics

- Natural organics

Organics with a molecular weight of 150–200 ppm and higher are rejected by the RO; however, a certain percentage of organics below that molecular weight will pass through the RO into the permeate.

Temperature

Temperature affects the flux rate for permeation. Cooler temperatures cause membrane pores to tighten, decreasing the flux rate. Warmer water loosens up the pores, allowing more total dissolved solids (TDS) or ions to pass through.

Orthophosphates in gray water or calcium in industrial reuse makeup streams can form calcium phosphate (a sludge-like deposit) in the last stage of the RO as the water gets warmer.

The solubility of silica and the flux, on the other hand, decrease as water temperature goes down, and vice versa.

Chlorine

Chlorine degrades RO membranes and needs to be removed either with uncatalyzed sodium bisulfite or an active carbon filtration system. If a transitional metal, such as iron, manganese, or cobalt, is present in a system containing chlorine, the rate of membrane degradation is accelerated.

Often, active carbon beds are paired with a biocide program. The two most commonly used in the industry are DBNPA and isothiazoline. These biocides help alleviate the microbiological activity on the membrane surfaces and the feedwater spacer, where bacteria are easily attached, thus reducing the potential of bacteria entering the system and feeding on the organics.

Chlorine is typically measured with an ORP in-line meter or a chlorine analyzer prior to entering the RO. It is a good practice to wet test for chlorine in addition to using on-line instrumentation.

Turbidity

Turbidity below 0.5 Ntu is a good target for makeup water, but low turbidity does not necessarily indicate the reduction of fouling potential; SDI testing provides more reliable insight.

If it is suspected that colloidal particles are entering the RO, run an SDI pad until it is plugged up and send the pad to the laboratory for a scanning electron microscope analysis. This test will indicate the characteristics of the atomic elements on the SDI pad, providing insight into what is fouling the RO.

Chemical Oxygen Demand (COD)

COD is found in gray water or industrial reuse and can be a major nutrient source for microbio.

A COD range of 8–10 mg/L is a good indication that the makeup source will have low fouling potential from COD.

Microbiological Matter

Two types of bacteria can be present in ROs: aerobic and anaerobic.

Aerobic bacteria

Classified by two types: planktonic and sessile

- Planktonic: free swimming

- Sessile: mature biological slime

Sessile bacteria are developed when aerobic bacteria are allowed to multiply and begin adhering to piping and membrane surfaces. This results in the aforementioned “flypaper” effect.

Best practice is to maintain microbio at 100 Cfu/mL in the feedwater and 1,000 Cfu/mL in the RO reject.

Anaerobic bacteria

- Typically found in ROs using gray or industrial reuse makeup.

- Iron-, denitrifying-, and sulfate-reducing bacteria are strong indications that mature biofilm has fully developed and microbiological control has been compromised.

Gases

Hydrogen Sulfide (H2S)

Normally, H2S is found in wells and is notable for its strong rotten egg odor. If oxidized or exposed to air, H2S can form elemental sulfur in the lead membrane, leading to potential blockage. To maintain system efficiency, the maximum level of H2S in RO feedwater is <0.1 ppm.

Hydrogen sulfide must be tested for on-site.

To test for H2S, fill up a water bottle halfway with makeup water, add a couple drops of hydrochloric acid into the bottle, shake, take the cap off, and smell. If hydrogen sulfide is present in the water, the odor will be apparent.

Carbon Dioxide (CO2)

As previously mentioned, the lower the alkalinity, the higher the CO2 content. Fortunately, CO2 does not play an active role in RO scaling or fouling. It passes directly through into the permeate.

It is important to monitor pH and alkalinity because they provide an indication of how much CO2 is flowing through the RO membrane. High amounts of CO2 can place a large load on the strong base anion and mixed bed.

Ammonia (NH3)

Ammonia is typically found in gray or industrial reuse makeup streams.

At a pH below 8.5, 90% or more of the ammonia is in its ionic form as NH4– and will be rejected in the RO like a monovalent ion. Above pH 9.5, ammonia becomes gaseous.

When mixed with TOC or phosphates, ammonia becomes suitable food for bacteria.

To test for ammonia, grab a water sample, add a few drops of 50% caustic, and shake the sample. If ammonia is present in the water, the strong smell will be apparent.

A Summary of RO Makeup Water Sources and Analysis Techniques

Surface Water

When using surface water for makeup, testing for microbio, organics, suspended solids, and colloidals is recommended. Season changes and shifts in weather conditions can cause rapid fluctuations in the levels of these components, so it is important to test frequently.

Well Water

Though well water quality is generally considered consistent, semi-annual testing is recommended, as it can have high mineral and hydrogen sulfide levels as well as some bacteria.

Gray Water

Various foulants in gray water may cause issues in RO systems, so frequent testing is recommended. It is important to test for bacteria and wash the cartridge filter housing regularly.

The Importance of Testing RO Makeup Water

Regardless of the makeup water source, we recommend trending water chemistry and other constituents and keeping trends on file. This data can assist in troubleshooting if RO problems arise.

As with all technology, due diligence is important to determine the feasibility of utilizing the methods outlined here. Always consult your equipment manuals and seek guidance from your water treatment representative to address plant-specific needs.

The post RO Makeup Water Sources: Addressing Variable Water Quality to Maintain System Efficiency appeared first on ChemTreat, Inc..

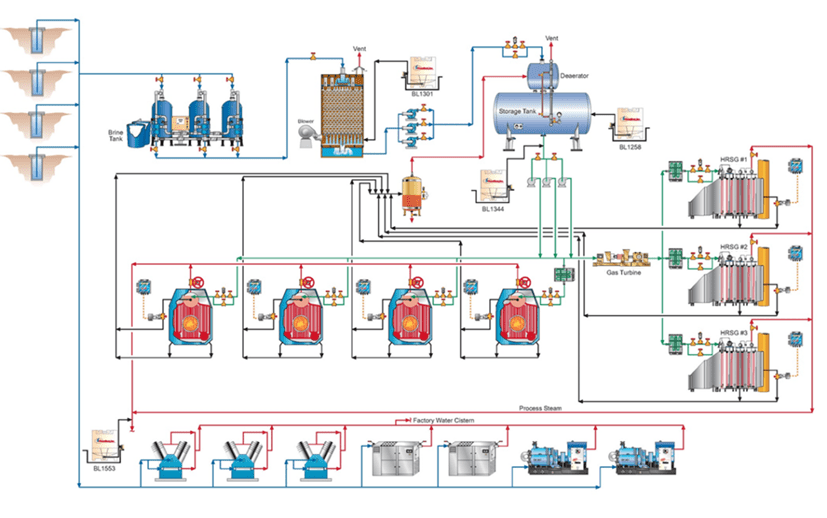

]]>The post Minimizing Corrosion and Deposition in High-Pressure, High-Purity Steam Generators for Chemical Processors appeared first on ChemTreat, Inc..

]]>This article provides:

- 1. A basic overview of high-pressure, high-purity steam cycle chemistry for the chemical, petrochemical, and refining industries

- 2. An introduction to the four pillars of steam cycle treatment

- 3. A discussion of typical steam generator issues at chemical processing plants, as well as opportunities for improvement

- a. Anionic and cationic impurities

- b. Corrosion and condensation

- c. Lack of steam quality monitoring and instrumentation

We hope this discussion will help chemical facility personnel improve the long-term production and reliability of their steam systems.

Why Boiler Water Treatment Matters

An Overview of High-Pressure, High-Purity Steam Cycle Chemistry

The primary purpose of boiler water treatment is reducing corrosion throughout the steam cycle.

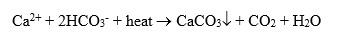

Treating boilers differs slightly from cooling tower, closed loop, and other chemical system treatment. For instance, true corrosion inhibitors are not added to a boiler system. Instead, aggressive anions like calcium, magnesium, chlorides, sulfates, and silicas are removed.

Oxygen is also removed via mechanical and chemical means.

Higher pH and temperatures stimulate the natural passivation processes that reduce corrosion and emissions, so boiler treatment typically involves raising the pH as well.

The secondary purpose of boiler water treatment is reducing deposition following pretreatment.

Iron and, to a lesser degree, copper deposition is particularly problematic, as it can transport into steam generators and boilers. Iron transported into boilers deposits in high heat flux areas, potentially leading to underdeposit corrosion.

The Four Pillars of Steam Cycle Treatment

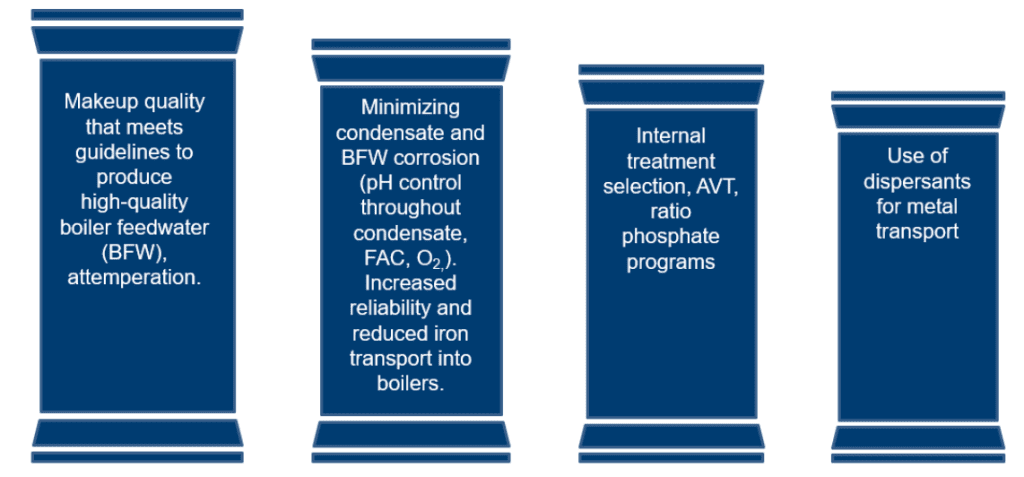

The four pillars of steam cycle treatment are a useful tool for understanding boiler treatment and the common gaps seen at chemical processing facilities.

In descending level of importance, the pillars are:

- 1. High-quality feedwater production

- 2. Condensate and corrosion reduction

- 3. Internal treatment selection and AVT

- 4. Dispersant treatment for metal transport

It is important to note that:

- If the first two pillars are addressed with minimal gaps, the second two pillars become less problematic.

- If there are gaps or failures in the first two pillars, the second two similarly matter less, as system reliability issues become more prevalent.

Pillar 1: Producing High-Quality Feedwater through High-Quality Makeup

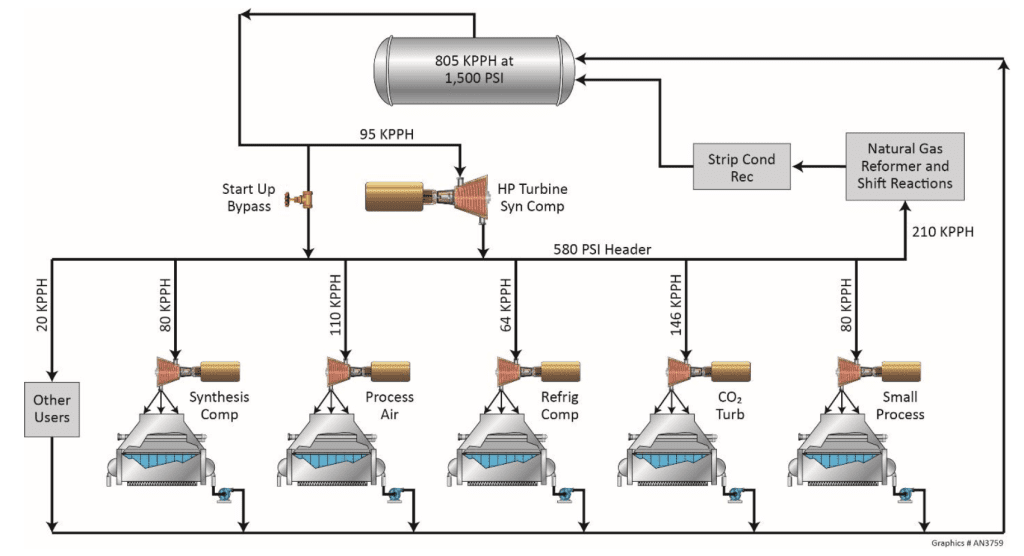

The first pillar represents a particularly challenging issue in the chemical processing industry. High-quality feedwater is created through the attemperation of high-quality makeup, otherwise known as boiler feedwater (BFW). This process involves controlling and measuring low-level ionic impurities to avoid boiler feedwater contamination, as contaminants can find their way into the steam through the attemperation process.

Pillar 2: Minimizing Condensate and Boiler Feedwater Corrosion

The second pillar focuses on minimizing condensate and BFW corrosion. This is typically accomplished by applying amines or ammonia, as well as through oxygen scavenging.

Generally, the goal is to minimize corrosion products and iron transport through the system. More specifically, we will explore flow-accelerated corrosion (FAC), another major gap faced by chemical and petrochemical plants as well as refineries.

Pillar 3: Selecting the Appropriate Internal Treatment

The third pillar addresses the importance of selecting the right steam gyrator and boiler internal treatment based on a system’s specific needs. This could include all-volatile treatment (AVT) ratio programs using sodium phosphate or all-polymer programs that can be used at lower pressures.

Pillar 4: Using Dispersants for Metal Transport

The last pillar refers to using polymers to disperse iron. In certain instances, this treatment is recommended for reducing iron transport into steam generators and boilers.

Three Common Steam Cycle Treatment Gaps in Chemical Processing Facilities

The four pillars provide a solid foundation for a deeper discussion into the specific challenges many chemical, petrochemical, and refining facilities face.

- 1. Anionic and cationic impurities

- 2. Accelerated corrosion and condensate

- 3. Lack of steam quality monitoring and instrumentation

1. Anionic Impurities and Cationic Impurities

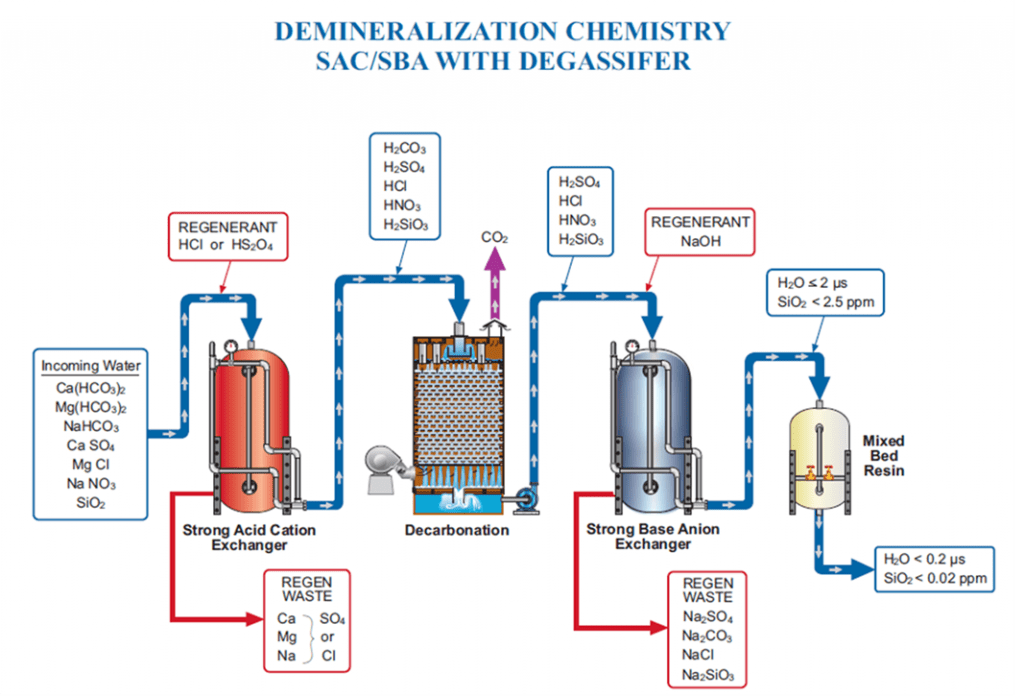

Feedwater quality is a major area of improvement for many chemical processors. In fact, demineralized water quality drives the majority of boiler chemistry needs.

Unfortunately, many plants do not follow best practices and operate boilers with low levels of ionic impurities in their makeup water. Controlling and measuring low-level ionic impurities is an important factor for maintaining boiler efficiency.

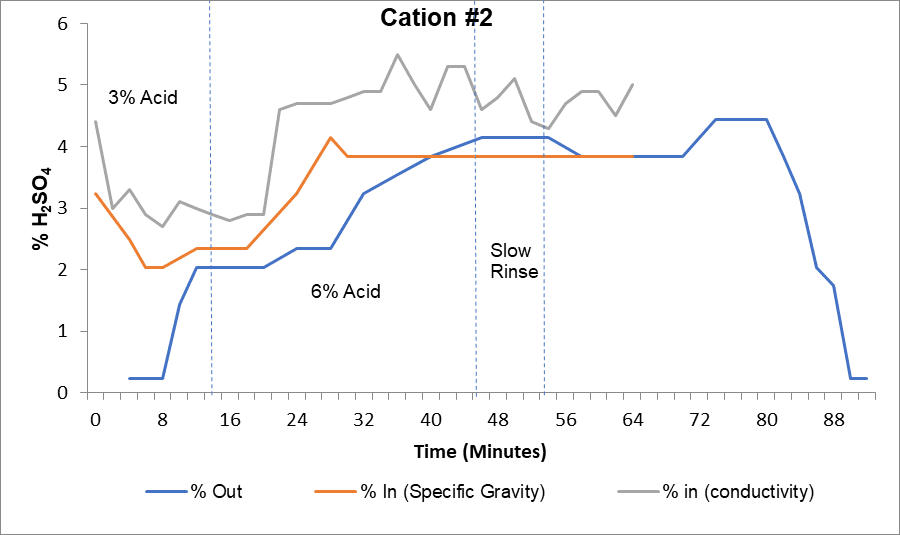

Cation Slipping

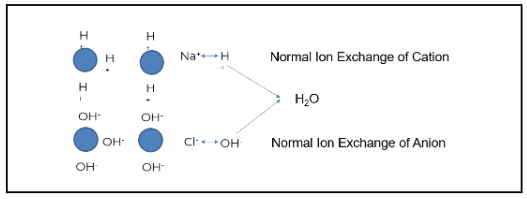

Plants typically use some form of mixed bed ion exchange to produce higher purity water.

The image above demonstrates how this process works when ion exchange is properly generated and operating as intended. The blue circles represent ion beads. When regenerated, the cation is loaded with a hydrogen or hydronium ion. The anion bead is loaded with a hydroxyl ion.

Using the example of salt (NaCl) and water (H2O), sodium (the cation) exchanges with a hydrogen ion. Chloride (the anionic portion) exchanges with a hydroxyl ion, creating pure water. Under the right conditions, regeneration produces high-quality feedwater. However, gaps such as cation bed slipping can occur when the ion exchange does not operate as designed.

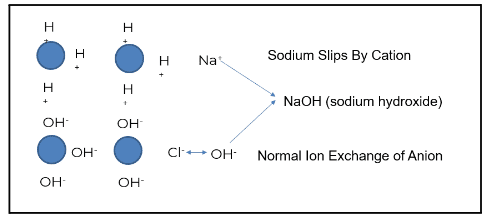

Sodium is a prevalent ion seen when the cation bed starts to slip. In the example above, sodium does not exchange with the hydronium or hydrogen ion; this is known as “slipping.” The slip causes the sodium to go through the chloride. Sodium chloride then exchanges out with a hydroxyl ion, and sodium slips as sodium hydroxide.

The sodium hydroxide will first concentrate in the boiler water, driving up boiler pH. This will increase the sodium-to-phosphate ratio, which, in turn, increases the risk of underdeposit corrosion and caustic gouging. Attemperation contamination reduces the steam quality for turbines, and calcium and magnesium can pass under more stressed conditions.

Even slightly elevated sodium levels pose a risk of sodium hydroxide formation in iron deposits. When this occurs, porous iron deposits in boilers (known as “wick boiling,” which will be discussed later in this article), the boiler water evaporates off, and high levels of iron concentrate remain.

If sodium hydroxide reaches the feedwater, which is normally used for de-superheating, it could directly contaminate the steam going to the turbine blades, reducing efficiency. Hydroxide can also deposit onto the turbine blades in the phase transition zone as it starts to condense, potentially causing stress corrosion cracking, usually on the roots, where the turbine blades attach to the rotor.

Under extreme conditions, as the cation resin is exhausted, the hardness ions of calcium and magnesium will start to pass, which can cause deposit issues in boilers at higher temperatures. Boilers are virtually intolerant to hardness at this level, and calcium magnesium can react with the alkalinity and start to drop out pH in the boiler.

Anion Slipping

Though not as common as cation slipping, anion slipping is an important point to discuss. Interestingly, slipping anions has the opposite effect of a slipping cation. The first anion we typically see slip is silica. Slipping silica combines with the exchanged hydronium ion, forming a slightly acidic species. Depending on the temperature, pressure, and pH, silica in these high-pressure, high-purity boilers is prone to mechanical and vaporous carryover in drums. This poses a risk to turbines; silica forms deposits on turbine blades, reducing efficiency.

Another problem with silica is that, unlike sodium, it cannot be removed with water washing. Silica forms a very tenacious deposit on turbine blades that is difficult to remove.

Other anions that can slip are chlorides and sulfates, which combine with the hydrogen ion to form mineral acids, such as hydrochloric and sulfuric acid, driving down boiler pH. These increase the risk of underdeposit corrosion in porous iron deposits.

If mineral acids enter the steam, they provide another mechanism for stress corrosion cracking in turbine blades.

2. Accelerated Condensate and Corrosion

When it comes to minimizing condensate and corrosion, the main priority is reducing levels of iron and other metal transport into the boilers.

Iron and Copper Transport into Steam Generators

Water systems in chemical processing facilities tend to be large, with complicated condensate systems and extensive steam cycles. Typically, the feedwater going into the boiler will have elevated iron levels, or even yellow metals. Any metal entering the boiler may deposit on boiler surfaces; it is difficult to keep them in solution in higher heat flux areas. This creates potential sites for underdeposit corrosion.

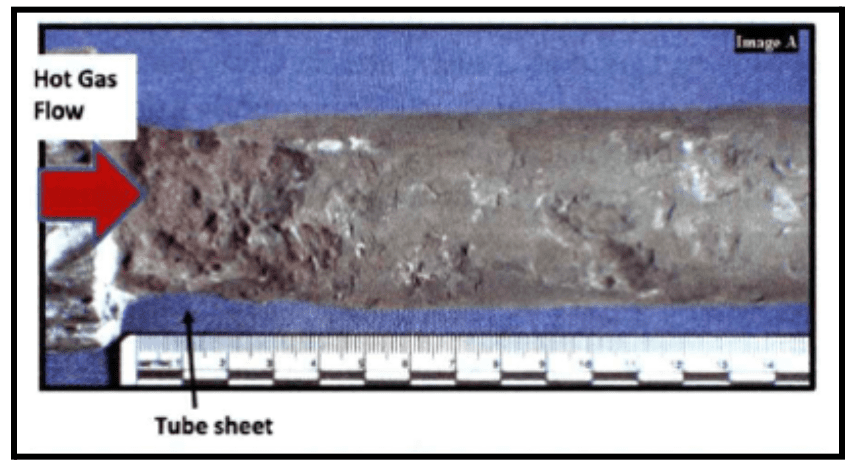

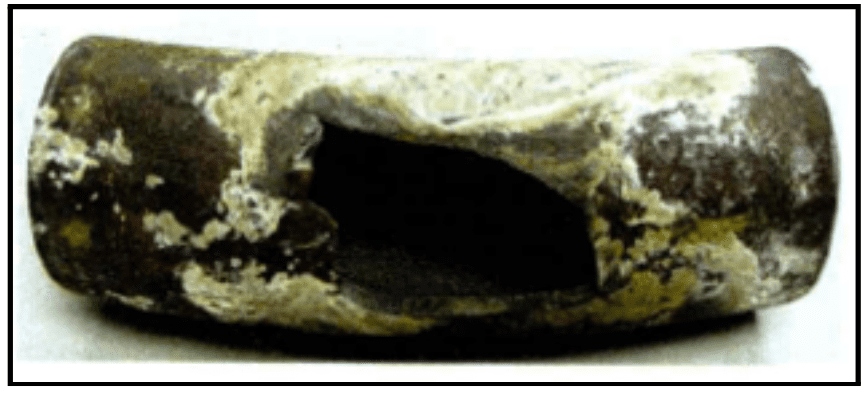

The following images show examples of underdeposit corrosion. The first is a transfer line exchanger (TLE) from a methanol plant, where waste heat gas was sent through the tubes. Acid phosphate wastage caused the formation of underdeposit corrosion sites. The plant had switched to a much higher-level sodium phosphate program years before, but the damage was already done.

The following images show examples of underdeposit corrosion. The first is a transfer line exchanger (TLE) from a methanol plant, where waste heat gas was sent through the tubes. Acid phosphate wastage caused the formation of underdeposit corrosion sites. The plant had switched to a much higher-level sodium phosphate program years before, but the damage was already done.

This represents a major challenge of underdeposit corrosion: once it occurs, bulk water chemistry will have minimal effect on existing underdeposit corrosion sites.

The second image is an example of a thick wall failure in a utility boiler. It shows an entire blowout, known as hydrogen damage. This was caused by a very acidic species depositing within the steel matrix and converting the carbon sites over to methane, leading the wall to expand and eventually resulting in the large failure seen here.

Image courtesy of Kurt Kraetsch, ChemTreat

These images illustrate the importance of pretreatment to boiler efficiency. Effective pretreatment reduces iron and other metal transport into the preboiler. Approximately 30% of iron entering a boiler remains soluble and is taken out via continuous blowdown.

Polymer treatment can help reduce metal transport and may be a good option for boilers with a history of underdeposit corrosion issues.

Wick Boiling

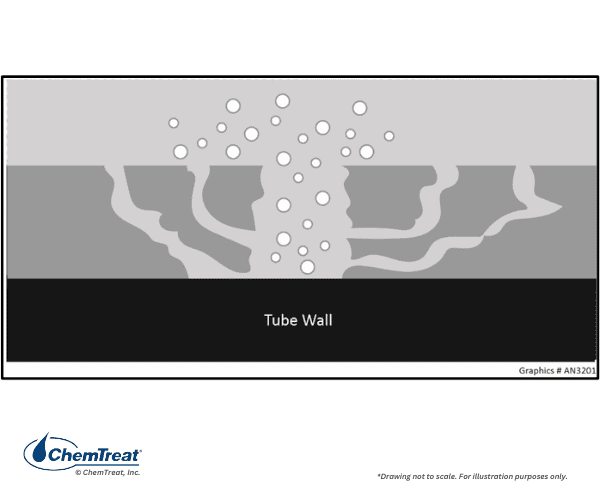

The following graphic demonstrates a principle called wick boiling, where porous iron deposits form on a boiler tube’s higher heat flux areas. These deposits occur when water with ionic impurities flows into the tube and evaporates off, creating high levels of concentration of these acidic and caustic species. This results in underdeposit corrosion in the form of tube wastage. Wick boiling typically causes hydrogen damage at a pH of 4, acid phosphate at low pH, and caustic gouging at high pH.

Balancing Mild Steel and Copper Corrosion in the Preboiler

Mixed-metallurgy boilers pose additional water treatment challenges. These boilers are typically made with mild steel and some form of yellow metal, such as copper and copper alloys like nickel and brass.

Copper and steel require completely different types of treatment to inhibit corrosion, which makes it difficult to calibrate treatment accordingly.

For copper, corrosion inhibition usually involves lowering pH to the 7–8 range. Higher levels of oxygen scavenger are typically added to accomplish this.

Mild steel, on the other hand, responds better to amines and a higher pH.

Balancing pH and amine/ammonia and oxygen scavenger feed is a constant challenge in mixed metallurgy systems.

Flow-Accelerated Corrosion: Feedwater and Condensate

Controlling flow-accelerated corrosion (FAC) presents one of the most significant gaps in water treatment for the chemical industry. FAC occurs when the rate of oxygen, or the rate at which the magnetite layer dissolves, is greater than its rate of formation.

Though this concept has long been well-understood, best practices for its mitigation has not been consistently applied in the chemical industry.

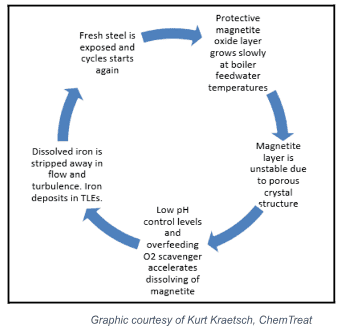

The following graphic illustrates the FAC cycle.

The process begins in the upper right-hand corner. The oxide layer grows slowly at first, as boiler feedwater temperatures are mild.

The magnetite layer continues to grow, developing an unstable, porous crystal structure.

Controlling ammonia/amine and oxygen scavenger comes into play at the next stage, as lower pH and high oxygen scavenger levels accelerate the dissolution of the magnetite layer.

As the iron is dissolved, it is stripped away in high-flow and turbulent areas, forming deposits in TLEs and boilers.

This leaves the fresh metal exposed, restarting the cycle.

Reducing FAC Potential with Feedwater pH Control

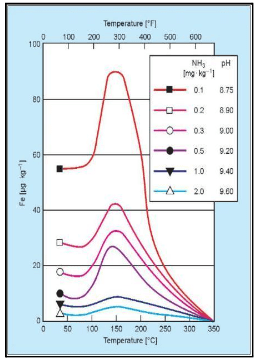

The graphic below shows the solubility of the magnetite layer, representing the risk of FAC.

The horizontal axis displays the temperature, while the vertical axis correlates to solubility. The risk peaks at approximately 300°F, or 150°C, which roughly corresponds to standard feed system operation, depending on deaerator pressure.

The individual-colored lines represent pH. As pH increases, the system’s ability to resist the dissolution of the magnetite layer increases. The highest solubility shown on this graph is a pH 8.75, dropping off significantly as pH increases to the 9.4–9.6 range. Thus, balancing feedwater and condensate operation at the highest practical pH, while effectively treating yellow metals, can be very difficult.

Understanding the Impact of Oxygen on FAC

The impact of oxygen on FAC is not well understood. Oxygen works synergistically with aggressive anions like chlorides and sulfates, causing corrosion. However, oxygen can also help reduce FAC.

As previously mentioned, the magnetite layer forming in feedwater systems is porous. If the gaps in the layer are filled with hematite by slightly increasing oxygen ingress, a stronger oxide layer will develop, which is less likely to dissolve and cause FAC.

In all-steel systems, pH is not always set as high as necessary, and reducing or removing oxygen scavenger application may help reduce FAC, depending on iron transport analysis.

3. Lack of Steam Quality Monitoring and Instrumentation

As with the improvement opportunities discussed in the previous section, following best practices around monitoring and instrumentation in steam systems is an important factor of effective water treatment.

Monitoring steam quality helps maintain the purity of the steam going to the turbines. Some common monitoring parameters are reviewed in the next sections, followed by a discussion of the benefits of using instrumentation over relying solely on sampling.

Sodium and Silica

Sodium and silica deposits, as well as aggressive anions like chlorides and sulfates, can cause stress corrosion cracking at the wet ends of turbine blades, reducing system efficiency.

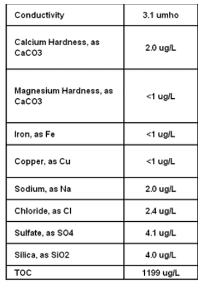

These analytical reports show the presence of various impurities in a 600-pound ethylene unit during standard operations versus a condenser leak. It is important to note the conductivity showed very little change during the condenser leak. This facility used ultra-low-level wet-based testing to track impurities but did not have sodium monitoring in place. Using instrumentation to monitor sodium may have caught the condenser leak earlier.

Monitoring feedwater and steam with instrumentation is a water treatment best practice. However, these systems may be difficult and expensive to retrofit and maintain.

One alternative is monitoring cation conductivity, which provides a good option for testing low-level ionic impurities.

Cation Conductivity Monitoring

There are two primary types of cation conductivity monitoring.

- 1. Degassed cation conductivity, where the water is boiled off, then cooled back down and run through a strong cation exchange column, typically to remove CO2. Newer units may use a nitrogen purge to remove CO2.

- 2. Un-degassed cation conductivity monitoring, in which water is run through the cation exchange column without being boiled off.

Photo courtesy of Hach.

Regardless of whether water is degassed, the key is to measure the conductivity before and after the cation exchange column.

Two Principles of Cation Conductivity Monitoring

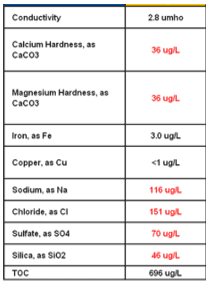

- 1. The majority of conductivity found in steam, feedwater, and condensate systems comes from adding ammonia or amines, not from ionic impurities. Monitoring cation conductivity removes the impact of ammonia or amines on the conductivity reading. The diagram below shows ammonia as ammonia hydroxide in water. The ammonium portion (the cation) will exchange out with a hydronium or hydroxyzine to form pure water, taking out the masking effect produced by amines or ammonia.

- 2. Cation conductivity converts low levels of impurities to acids, which are always more conductive than their neutral salts. During a condenser leak or a period of poor ion exchange, sodium chloride is a typical impurity. The sodium in sodium chloride exchanges out with a hydronium hydroxyl or hydrogen ion to form hydrochloric acid, amplifying the conductivity’s effect by taking low part per billion levels of ionic impurities and converting them into acids.

- a. During the ethylene unit condenser leak shown previously, there was a slight uptake in normal, un-neutralized, or non-cation, conductivity. The average conductivity increased from 3–4.5 to 3.5–4.5. It would typically be difficult to note this difference; however, the cation conductivity shot up by a factor of 10In areas such as feedwater, steam, and condensate systems, cation conductivity offers an efficient way to measure and monitor very low levels of ionic impurities via instrumentation.

The Benefits of Instrumentation Over Sampling

The example above illustrates the importance of instrumentation in helping facilities catch boiler system issues.

Some chemical processing plants still rely solely on “grab” samples, which provide an incomplete picture of the system water quality. Particularly in high-pressure, high-purity units, monitoring with instrumentation is best practice, with grab sampling used only as a backup.

Conclusion

Minimizing corrosion and deposition in high-purity, high-pressure steam generators and boilers is an important component of maintaining system reliability and efficiency in chemical, petrochemical, and refining facilities.

When designing a water treatment program, it is important to keep the four pillars of steam water treatment in mind, as well as identifying areas of improvement based on common gaps.

The ultimate goal of this post was to address these gaps in high-purity, high-pressure steam generator treatment and help your facility improve the long-term reliability of your boilers and steam turbines by implementing best practices around treatment chemistries and monitoring.

As with all other technologies, due diligence is necessary to determine the feasibility of utilizing the methods discussed in this post. It is important to consult your equipment manuals and guides and seek guidance from your local water treatment representative to address the specific needs of your facility.

The post Minimizing Corrosion and Deposition in High-Pressure, High-Purity Steam Generators for Chemical Processors appeared first on ChemTreat, Inc..

]]>The post Three Key Performance Indicators for Monitoring Reverse Osmosis Units appeared first on ChemTreat, Inc..

]]>When operating and maintaining reverse osmosis units in a pretreatment system, there are three key performance indicators (KPIs) to keep in mind:

- Normalized permeate flow

- Pressure change (ΔP)

- Salt passage

However, not all RO systems are built the same. Each manufacturer has specific guidelines for managing their RO units.

RO Cleaning Industry Guidelines

Some operators incorrectly believe their RO units should be cleaned every 3–4 months, but RO manufacturers have differing recommendations for their systems. The parameters for cleaning are outlined below by manufacturer.

- Permeate flow rate drops 10%

- Normalized flow passage increases 5–10%

- Normalized pressure drop increases 10–15%

- Permeate flow decreases by 10%

- Permeate quality decreases of 10%

- Normalized pressure drops 15%

- High fouling levels occur at double the above rates

- Permeate flow decreases by 10% since startup or last cleaning

- Salt passage increases by 10% since startup or last cleaning

- Normalized pressure drops 15% since startup or last cleaning

- Normalized differential pressure increases by more than 20%

- Permeate flow decreases by more than 10%

- Salt passage increases by more than 20%

All manufacturers listed above offer free, downloadable manuals and technical bulletins on their websites. For more detail, please refer to their official websites. Please note this list of manufacturers is not exhaustive.

Sometimes, these guidelines are not followed because upstream pretreatment and filtration systems are not maintained properly, resulting in the need for weekly RO cleanings.

The Importance of Trending Data

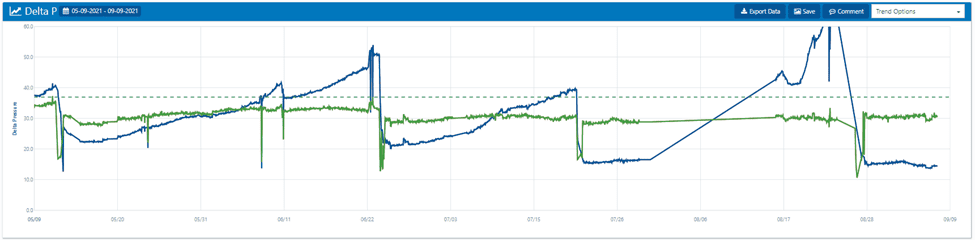

When RO parameters aren’t recorded and trended on a regular basis, tracking performance issues becomes difficult. Without proper data trending, permeate flow is only observed when it begins to drop or conductivity increases.

Many operators will wait until they experience a ΔP increase of 40–50 psid across a single stage before initiating a cleaning. Such a significant pressure increase often leads to channeling, where gaps from suspended solids, colloidals, and bacteria pack into the RO. These gaps restrict flow through the unit, creating a flow of least resistance during cleaning.

RO Trending and Maintenance Best Practices

We recommend using manufacturers’ guidelines to establish targets for normalized permeate flow, ΔP, or permeate conductivity increases.

When ΔP increases, it is time to start scheduling maintenance and cleaning procedures.

Key Parameters to Monitor

Monitor ΔP across each stage, not the entire RO

Carefully monitor the first stage if using surface water as makeup. Colloidals passing through into the cartridge filter will cause a ΔP increase into the RO.

If the first stage is experiencing buildup, take an SDI pad and allow it to run until it plugs off.

Send the SDI pad with a couple drops of permeate water to your water treatment provider for a scanning electron microscope and foulant identification to help identify pretreatment issues.

Temperature

- Membranes tighten up as the water gets colder, reducing permeate conductivity.

- Conversely, RO membranes loosen up as the water gets warmer. Warmer temperatures increase permeate conductivity. Organics levels will also rise, subsequently increasing the presence of bacteria in the system.

Free Chlorine

- Free chlorine levels should be maintained at 0.0 ppm for proper operation. When adding a DPD powder pillow, the resulting sample should always be clear with no pink color.

- If using an ORP monitor, DuPont’s FilmTec manual recommends less than 200 millivolts of free chlorine. If using wastewater or gray water, the recommended levels are less than 300 millivolts. However, whenever using ORP, the probe should be calibrated either weekly or biweekly.

Microbiological Fouling

- Microbiological fouling can increase RO pressure. Limits are 100 CFUs/mL in the makeup or 1,000 CFUs/mL in the reject. If these limits are exceeded, a biocide program is recommended.

Feedwater Conductivity and Turbidity

Many RO makeups have two or more streams with different influent conductivity. Use of an on-line conductivity meter allows you to monitor the incoming conductivity to better predict the impact on the permeate. We recommend trending RO conductivity as a best practice for maintaining your RO.

Monitoring an RO System

Proper monitoring of an RO system enables operators to know where fouling will occur and what cleaner to use.

RO manufacturers offer free downloadable trending software, but a spreadsheet can also be used to record and trend data.

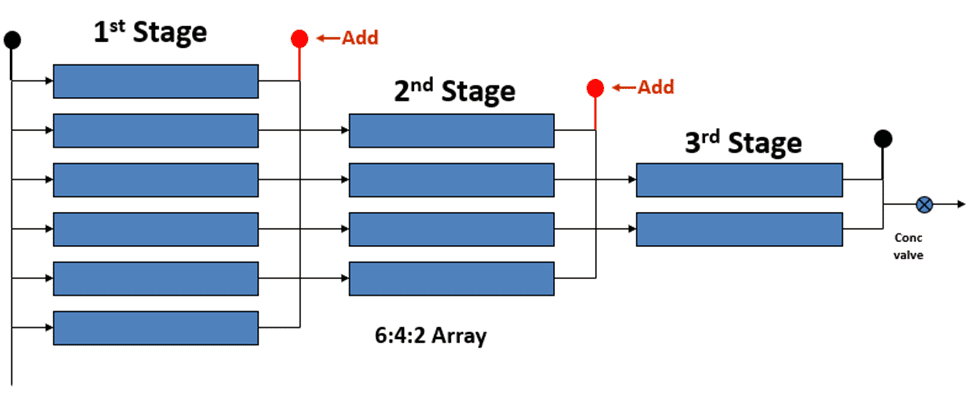

A flow meter on the permeate, between the first and second stage, allows for individual trending and targeted cleaning of the two stages.

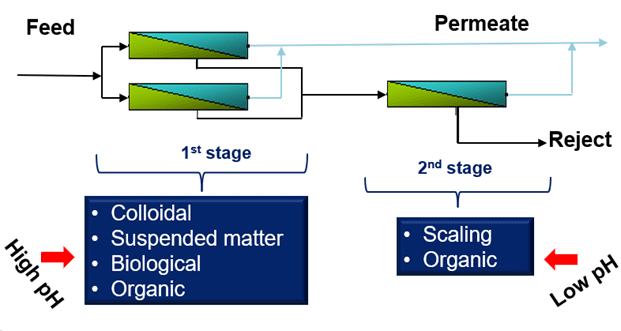

A first stage ΔP is indicative of biofouling, colloidals, suspended solids, or organics. A second stage ΔP increase mainly indicates scaling.

High-pH cleaners are recommended for high first stage ΔP. Anything not properly treated in the first stage will be pushed into the second stage of the RO. However, if the correct antiscalant is selected to match the incoming chemistry and the recovery rate does not change, scaling should not typically occur.

The Importance of Inspecting Cartridge Filters

Monitoring cartridge filters and changing them out regularly are important steps that often get overlooked. If any sand, particles, or grit are found on the outside of the cartridge filter elements, something upstream has been breached from one of the bottom laterals or a vessel flange that needs to be corrected.

When opening RO membranes, contaminants from the softener, anthracite, or multimedia may be found in the lead element. These cannot be removed with cleaners and must be flushed out through the bottom drains of the cartridge filter housing.

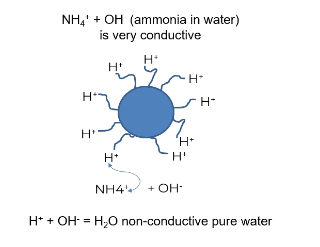

Both cartridge filter drain valves (as pictured below) should be opened when changing out cartridge filters.

The bottom drain valve should be installed in an easily accessible location. If these are not flushed, foulants will be sent to the bottom compartment and into the lead membrane.

Case Study: Cartridge Filter Fouling Causes RO Issues

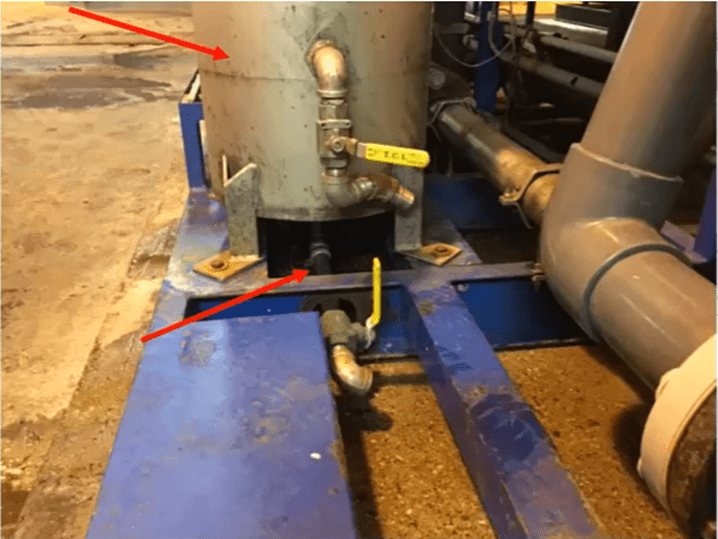

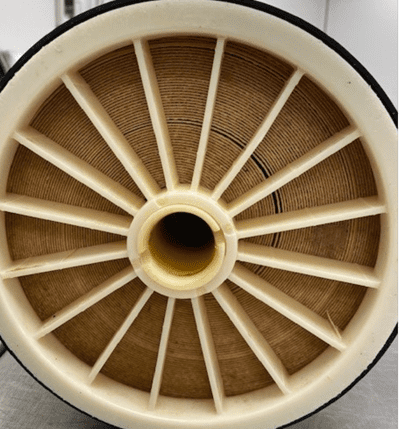

A plant was experiencing consistently high ΔP. In the photo below, there is brown debris built up at the base of the stay rods, around the holes meant for filtered water. Any debris not flushed out of the cartridge filter housing will be pushed into the bottom compartment and the lead element. When this happens, it is very difficult, if not impossible, to remove what is lodged into the face of the lead membrane with RO cleaning chemicals.

Notice the wide gaps in the membranes below. These were caused by colloidal and particle fouling. Once a gap of any size develops, a flow of least resistance is created, preventing proper filtration or cleaning.

Inspecting the Cartridge Filter Housing

Cartridge filters offer a window into RO operations and are the last means of defense against filtration issues. Let your eyes and your nose be your guide. If something does not look right, report it. If you observe an odor, feel any slime, or notice grit, start to look upstream for the source of the issue and correct it.

Monitoring Guidelines for RO Systems

Monitor conductivity in the feed, permeate, concentrate, or reject.

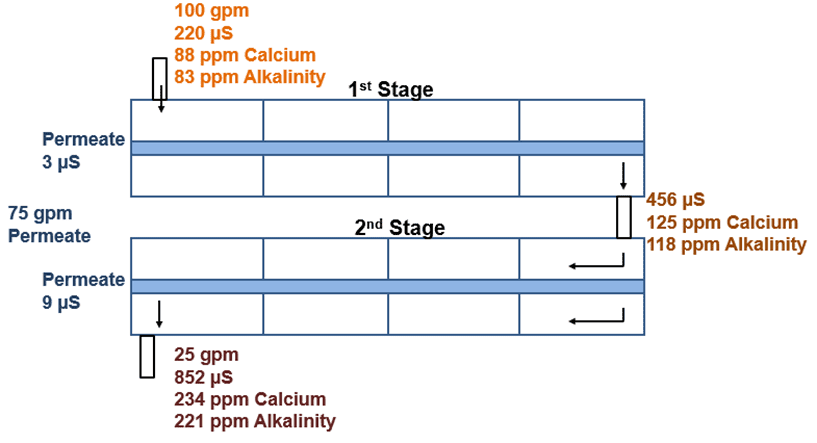

Sample all ions frequently. What comes in, must go out or be rejected. For example, if running at 75% recovery, everything coming in should be cycling up four times; if there is 100 ppm calcium coming in, there should be 400 ppm going out.

Measure and record the flow of feed, permeate, and concentrate or reject.

Monitor pressure in the feed, interstage, concentrate, and permeate.

If there is not a pressure gauge in the interstage, see if it is feasible to have one installed. This will act as an indicator for the first stage, where most RO fouling occurs.

Measure the pressure in the concentrate.

Keep an eye on feed temperature, pH, and ORP.

Understanding the conditions of all RO stage flows and ΔP allows for proper cleaner selection and targeted cleaning.

RO Readings

Enter all RO readings into a spreadsheet for trending purposes or download the trending software from your RO manufacturer.

First Stage

The first stage experiences the highest flow rate and the lowest incoming conductivity. As a result of the high flow rate, the first stage is prone to bacteria, colloidals, suspended solids, and organics. Coagulant fouling may also occur. High-pH cleaners are used in this stage to mitigate these issues.

Second Stage

The second stage has the highest conductivity. Carbonate, sulfate, hydroxide, and phosphate scaling may occur in the second stage. Low-pH cleaners are paired with the proper antiscalant for second stage cleaning. The exception is silica scale, which necessitates a high-pH cleaner.

The Importance of Data Normalization

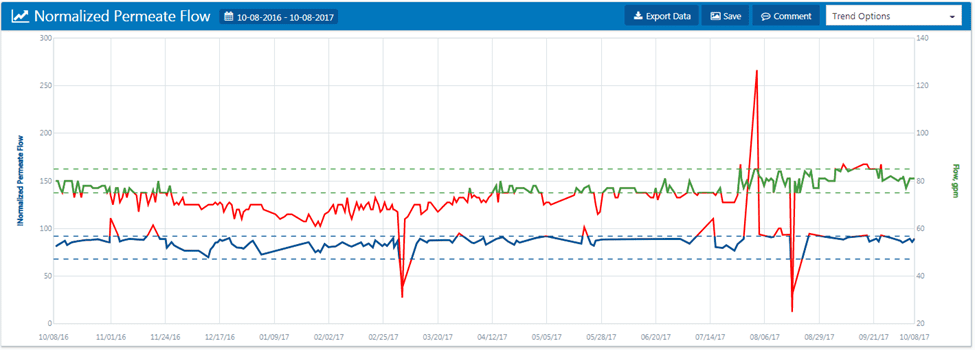

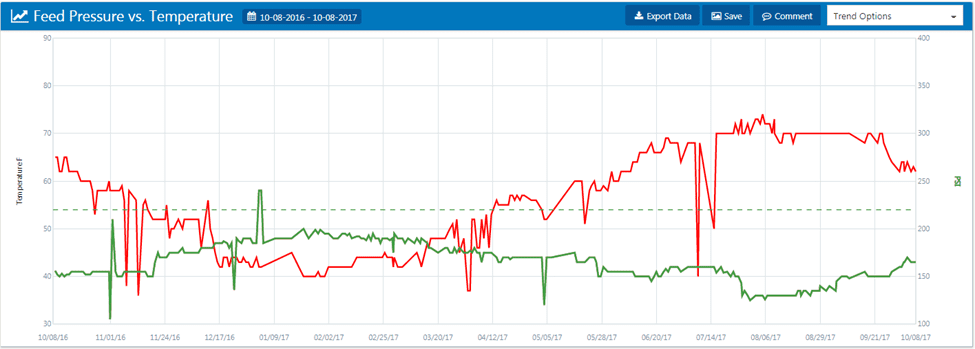

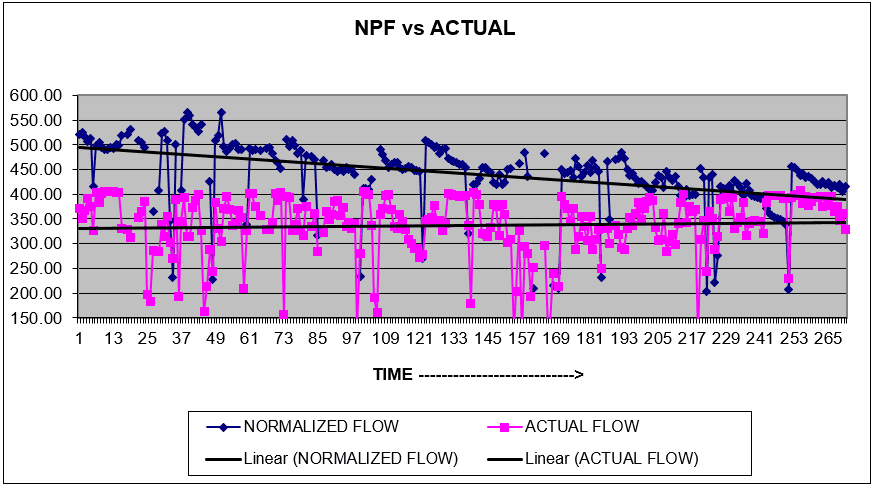

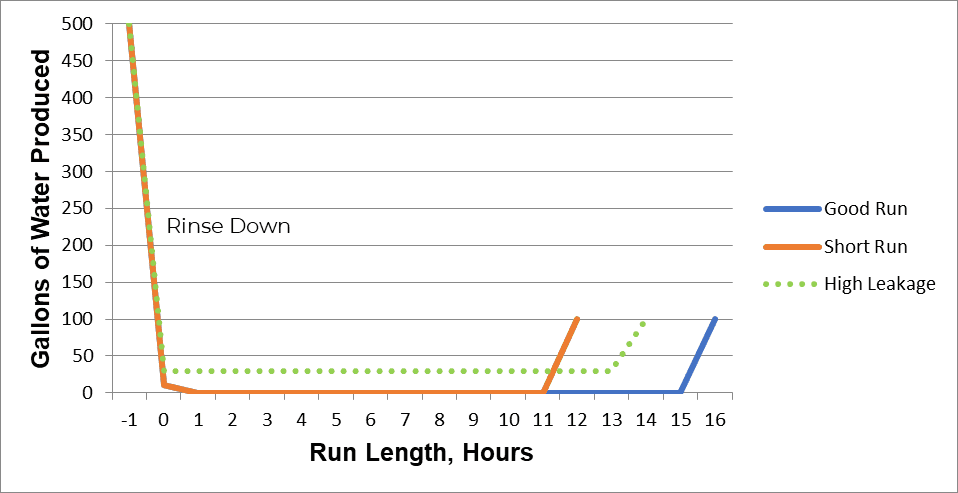

There are two trend lines in the below graph.

The blue line indicates normalized flow, which is a relatively straight line. The peaks and valleys are called “fat fingers,” caused by operators mistyping data points and creating outliers.

The top line trends permeate flow. While the permeate flow fluctuates during normal operation, it may indicate the need for cleaning.

When considering the normalized line, note whether the flow remains within its standard limits. If it does, the RO does not need to be cleaned. Normalized trending also accounts for temperature fluctuations.

In the graph below, the red line indicates feedwater temperature, and the green line indicates pump pressure.

As feedwater temperature decreases, RO pressure increases because of water’s increased viscosity. More importantly, the membrane pores begin to tighten up in cooler temperatures, causing pumping pressure to increase and permeate conductivity to decrease slightly.

The Consequences of Not Trending and Normalizing RO Data

According to the DuPont FilmTec RO manual, page 130, “if you wait too long, cleaning may not restore the membrane element performance successfully. In addition, the time between cleanings becomes shorter as the membrane elements will foul or scale more rapidly.”

If an RO is not taken out of service and cleaned in a timely manner, channeling or gaps may develop, and cleaning may no longer restore the unit’s baseline. It is very important to monitor trends and clean ROs when necessary.

The above shows a very good example of normalized versus permeate flow. The trend lines appear rather busy; however, the dark blueline of the normalized permeate flow is slowly falling and never returns to the baseline. This indicates the operator has waited too long to clean the RO.

It is important to be proactive when noting a downward trend. In this example, operators should set up the clean-in-place (CIP) and schedule a cleaning. Otherwise, the membranes will eventually need to be replaced.

Waiting Too Long to Clean an RO

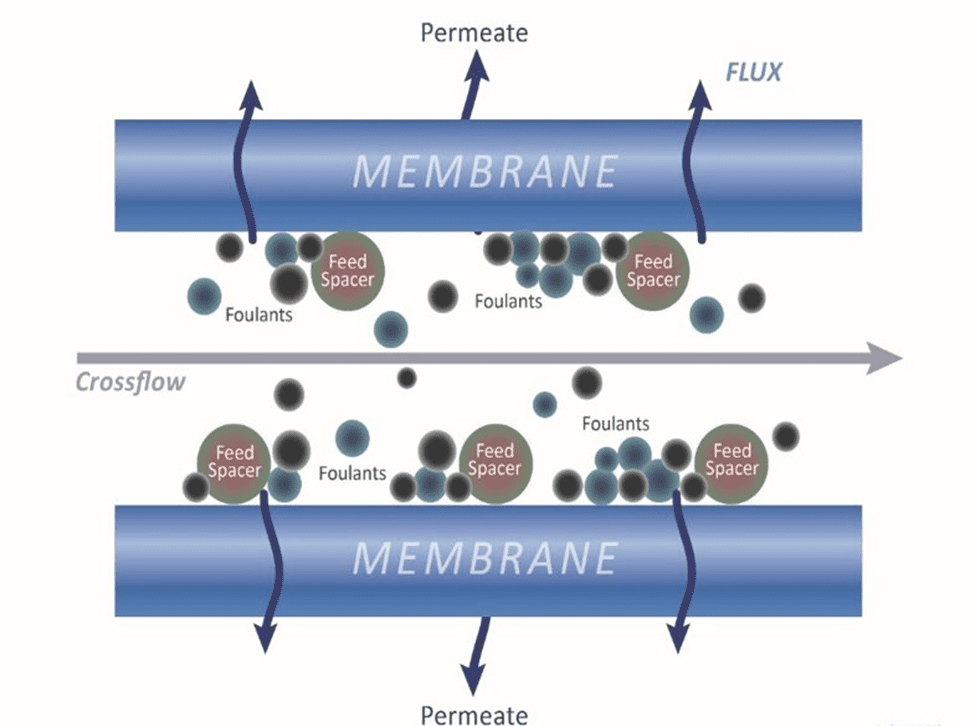

In the schematic below, the blue bar represents the membrane sheet, and the brown circles represent the feed spacer. As feedwater flows through the RO, colloidals and bacteria will become packed in the feed spacers. Bacteria excrete polysaccharides, which will attract and trap colloidals and suspended particles that are difficult to clean out.

These trapped foulants require a more aggressive cleaning treatment or a very high-pH cleaner to treat. The more the ΔP is allowed to increase, the more difficult cleaning becomes.

Notice the two narrow crescent-shaped gaps in the membrane above. Once a gap forms, they are permanent and cannot be undone. Service flow and cleaning chemicals will follow the path of least resistance through these gaps, making cleaning more difficult.

In some instances, the gaps become so enlarged that the ΔP will increase and then plateau, so there is no more ΔP building up in that membrane. When this occurs, the areas without water passing through will become stagnant, causing a virtual dead zone.

Six Key Takeaways

The following best practices are recommended for maintaining RO efficiency.

- Monitor the first stage ΔP closely, especially if using surface water. Make it a habit to scan the first stage ΔP and temperature.

If temperature decreases, the ΔP and pump pressure will increase because the membrane pores are going to tighten up. That does not mean cleaning is required in this instance. Look at the normalized data.

- Adhere to target set points for RO cleaning. Most of the time, fouling will occur in the first stage, particularly if using surface water.

If water chemistry is being monitored and trended, RO scaling will become evident. When a proper antiscalant is used and the recovery rate does not change, last stage scaling is not typically a concern.

- Monitor for microbiological activity in the feed, reject, and cartridge filter housing. Even with the targeted chemistry levels, 3 ppm total organic carbon (TOC) or higher will provide food for bacteria.

- Observe the cartridge filter housing. Smell and feel for the presence of slime. Check the condition of the internal surfaces: look for chips.

- Monitor permeate conductivity. If the permeate conductivity is increasing, determine whether temperature has changed, or the incoming conductivity has increased.

- Watch for any free chlorine entering the RO membrane. 0.0 ppm and a clear color on the DPD test indicates the absence of free chlorine.

The more data is gathered and trended, the easier troubleshooting RO issues becomes. Data collection and normalization enables operators to schedule cleanings and ensure the necessary manpower, chemicals, equipment, etc. are available.

Monitoring these six key areas of the RO provides operators with the necessary understanding of how the three KPIs are trending, indicates the conditions impacting the RO, and helps avoid RO autopsies.

As with all technologies, due diligence is necessary for determining the feasibility of utilizing these methods. Always consult your equipment manuals and guides and seek guidance from your water treatment provider to address your specific system needs.

References

DuPont . Feb 2023, Version 16. FilmTec

. Feb 2023, Version 16. FilmTec Reverse Osmosis Membranes Technical Manual. Retrieved from: https://www.dupont.com/content/dam/dupont/amer/us/en/water-solutions/public/documents/en/RO-NF-FilmTec-Manual-45-D01504-en.pdf.

Reverse Osmosis Membranes Technical Manual. Retrieved from: https://www.dupont.com/content/dam/dupont/amer/us/en/water-solutions/public/documents/en/RO-NF-FilmTec-Manual-45-D01504-en.pdf.

The post Three Key Performance Indicators for Monitoring Reverse Osmosis Units appeared first on ChemTreat, Inc..

]]>The post Film-Forming Amines: Innovative Boiler Treatment Technology for the Refining Industry appeared first on ChemTreat, Inc..

]]>This innovative technology can be particularly beneficial for refineries, where maintaining utility system conditions is important for production efficiency.

Film-Forming Amine Treatment vs. Traditional Boiler Treatment

Traditional boiler treatment programs do not generally include a corrosion inhibitor. Pretreatment is used to reduce scale and corrosive ions, and oxygen levels are reduced via mechanical and chemical means. pH is raised to passivate metal surfaces, and temperature is increased to deoxygenate the water through a deaerator, helping build the passive layer.

In complicated systems such as those seen at refineries, these standard processes may not achieve the desired level of corrosion inhibition. Film-forming amines can be a beneficial supplement to the treatment program, as they bind directly to the metal surfaces, where corrosion is typically more difficult to treat.

Benefits of Film-Forming Amine Treatment for Refinery Operations

FFA programs have primarily been used in power industry applications in the past. However, they can offer significant benefits to applications specific to the refining industry.

Soft Water Systems

In combination with an existing corrosion inhibition program, FFA can help:

- Reduce amine usage

- Treat complicated and extensive condensate systems and reboilers, as well as mixed-metallurgy systems containing copper and iron

- Inhibit corrosion during layup periods

Higher Purity Systems

FFA can help reduce corrosion in the following higher purity systems:

- Low-pressure waste heat boilers such as SRU condensers

- Mixed metallurgy systems balancing pH and oxygen scavengers

- Condensate and feedwater systems, where reducing iron and copper transport via corrosion inhibition may help reduce the risk of underdeposit corrosion.

These products also help reduce flow-accelerated corrosion and issues related to layup.

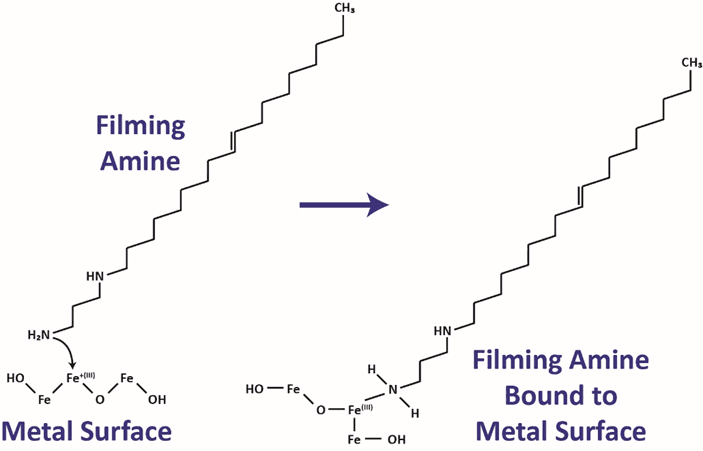

What are Film-Forming Amines and How Do They Work?

Film-forming amines contain a long chain hydrocarbon as part of the molecule. The amine portion of the molecule allows it to form an attachment to the copper or iron within the oxide layer on the metal surface. The hydrocarbon portion of the molecule repels water, inhibiting water transport to the surface where the film is formed.

In traditional treatment, mild steel develops a passive oxide layer by building layers of magnetite particles that get progressively less organized and irregular in shape as they move away from the surface. The stacking of these particles decreases the corrosion rate so smaller, more organized particles result in decreased layer depth. Particle size is strongly influenced by the solubility and mobility of the magnetite particle as well as the oxidation rate of the corroding ferrous iron from the metal surface.

A low concentration of oxygen increases the oxidation rate of ferrous iron dissolving from the surface, which both increases magnetite formation and allows for the formation of low concentrations of hematite.

Hematite forms an iron oxide polymer that interacts with the magnetite, decreasing its mobility. This reduces the particle size and cements the particle in place, allowing for a more compact, passive, and stable iron oxide layer.

With FFA treatment, the epitaxial layer is depleted, and a film is formed to create a hydrophobic surface. If the FFA residual is decreased below a film maintenance level, the epitaxial layer will regrow to its original depth.

FFA treatment will remove the less organized top portion of the iron oxide layer because it is not bonded with the other particles as effectively. Once the looser iron oxide layer is removed, the film starts to build and increase in density as more treatment is added.

Measuring Hydrophobicity

A successfully applied FFA program will create a hydrophobic layer on boiler surfaces.

Image of a steam drum with a hydrophobic layer of FFA. Water droplets stay on the surface of the drum without being absorbed into the surface and causing corrosion.

Preparing for FFA Application: What You Need to Know

Prior to feeding FFA treatment in your boiler systems, several factors may need to be considered. These include, but are not limited to:

- Water analysis data: is water chemistry on target based on industry guidelines?

- Where does the water go?

- What percent of condensate is returned?

- Does condensate get polished?

- Are there any blowdown restrictions?

- Historical data

- pH trends for drums, steam system, and hotwell

- Iron residual trends for drums and hotwell

- Cation conductivity trends in the hotwell

- Deposit weight density

- Boiler inspection reports

- Pictures of drum internals

- Economizer and evaporator tube wall thickness measured by ultrasonic testing

How is FFA Treatment Performance Measured?

To monitor the effectiveness of FFA treatment, tracking the following parameters is recommended:

- Iron residual reduction (benchmarked against historic iron residual levels)

- Reduction in corroding areas (benchmarked against past inspections)

- Hydrophobicity

- Integrity of the piping based on surface analysis

Frequently Asked Questions

Does ChemTreat feed FFA as a stand-alone program for deposit, scale, and corrosion control?

ChemTreat does not feed FFAs as a standalone program. We feed film-forming amines as a supplement to traditional treatment programs for systems that need an enhanced level of corrosion inhibition.

Does this technology “gunk up” like previous generations utilizing octadecylamine (ODA) chemistry?

ChemTreat’s FFA technology is more volatile than products such as ODA and does not have the same solubility issues. Filming amines can also be tested to verify that product is not being overfed. FFA application has not caused issues such as gunking, probe fouling, strain clogging, etc.

Are filming amines sensitive to pH?

Unlike previous generations of this technology, ChemTreat’s filming amine is not pH-sensitive, so the hydrophobic layer stays intact if pH increases.

Do filming amines bind catalyst sites?

ChemTreat’s FFA technology has been fed in systems where steam directly contacts with catalyst sites, and we have not observed the product binding with catalysts. Catalysts are very active sites that operate at a temperature above the stability of FFAs, so we would not expect filming amines to bind with them.

Is FFA the Right Treatment Solution for my Refinery?

As with all other technologies, due diligence is necessary to determine the feasibility for utilizing the methods discussed in this post.

It is always important to consult your equipment manuals and guides and seek guidance from your local water treatment representative to address your specific needs.

Contact ChemTreat today to see if FFA treatment is right for your facility.

The post Film-Forming Amines: Innovative Boiler Treatment Technology for the Refining Industry appeared first on ChemTreat, Inc..

]]>The post <strong>LEED Certification: How ChemTreat Can Help</strong> appeared first on ChemTreat, Inc..

]]>ChemTreat offers support to companies seeking LEED certification in several areas.

ChemTreat Support for LEED Certification

Programs to Help You Earn LEED Credits

Our experienced team can provide support in the following areas:

- Reducing the carbon footprint of cooling and heating systems by using locally manufactured products and low-carbon raw materials

- Reducing carbon emissions from operations or capturing carbon from processes using flue gas scrubbers for facilities with waste treatment plants

- Helping facilities go carbon negative by converting atmospheric carbon dioxide into carbonate alkalinity, which can be separated out in a treatment plant

- Improving system efficiency by treating cooling systems and air scrubbers to reduce pathogens, remove volatile organics and other air pollutants, and mitigate corrosion

- Reducing the toxicity of the waters discharged from cooling and heat systems

- Lowering air pollution from cooling tower plumes that may contain toxic or harmful substances or large particulate emissions

Designing a New Facility

Get in touch with our team as early as possible in your design phase. We can help with:

- Devising an optimal cooling system with minimal blowdown so you can get the most out of each gallon of water you use

- Planning out efficient heating and boiler systems that capture returned condensate and pull heat from discharged water, so BTUs are not sent to the drain

- Assisting with the creation of a zero-liquid discharge (ZLD) facility, which may involve installing clarifiers or filtration, softeners, and/or reverse osmosis (RO) systems

Certifying an Existing Facility

We also support existing facilities looking to get LEED certified. Our team can help with:

- Auditing current energy and water consumption to identify gaps and recommend process improvements, including system cleanings and treatment program optimizations

- Supporting facilities looking to transition to Zero-Liquid Discharge by advising on equipment and facility needs

If you’re looking to earn LEED credits at your facility, contact ChemTreat today and let us help you on your journey toward meeting your environmental goals.

The post <strong>LEED Certification: How ChemTreat Can Help</strong> appeared first on ChemTreat, Inc..

]]>The post <strong>Reduce, Reuse, Recycle: Promoting Sustainability and Efficiency in HVAC Systems</strong> appeared first on ChemTreat, Inc..

]]>Water and Energy Consumption Overview

The primary consumers of water and energy in HVAC systems are boilers, closed loops, and cooling systems.

Boilers

In general, boiler systems provide heat for HVAC and other processes, consuming quite a bit of energy and potentially large amounts of water.

Closed Loop Systems

Closed loop systems are filled with a set volume of water, and they do not consume much water unless experiencing a leak. However, they do consume energy by pumping water around a facility, generally for heating and cooling purposes.

Cooling Towers

Evaporative cooling towers consume a great deal of water and are one of the most efficient methods for ejecting heat from inside a building or facility to the atmosphere.

Water Cooling

Chillers

Air-cooled chillers require approximately 1.5 kilowatts per ton of cooling, whereas water-cooled chillers use approximately 0.85 kilowatts per ton. A ton of cooling is equivalent to 12,000 Btu’s.

Air-cooled chillers have a much lower daily capacity than water-cooled chillers because they require more surface area. Their capacity is typically limited to 7.5–500 tons of cooling, whereas water-cooled chillers can be quite large, with a capacity of up to 4,000 tons.

| Air-Cooled Chillers | Water-Cooled Chillers | |

| Efficiency | 1.5 kW/ton of cooling | 0.85 kW/ton of cooling |

| Capacity | 7.5–500 tons | 10–4,000 tons |

Cooling Towers

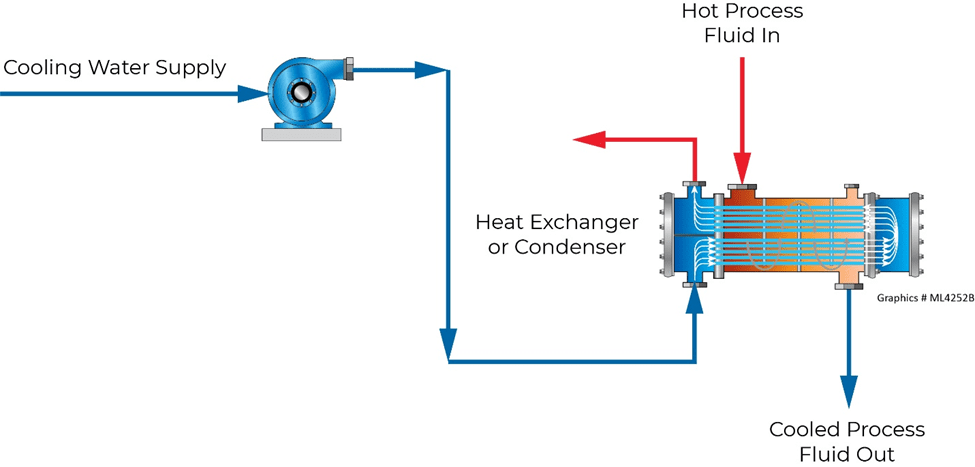

The purpose of an evaporative cooling tower is to maximize the surface area of the water flow to transfer heat to the atmosphere through evaporation of water. Air is pulled up through water falling through or spraying down through the cooling tower, and heat is drawn out. This process can waste a great deal of water if not optimized with proper treatment and control; therefore, cooling towers should be one of the first pieces of equipment you evaluate when looking to reduce water usage.

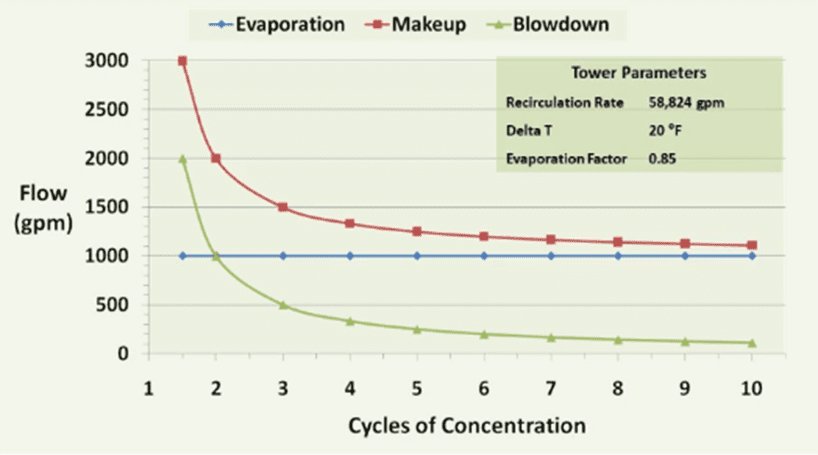

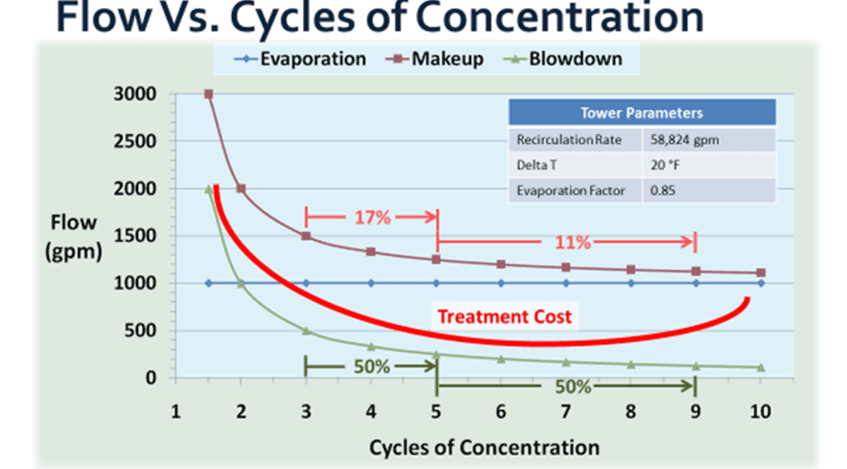

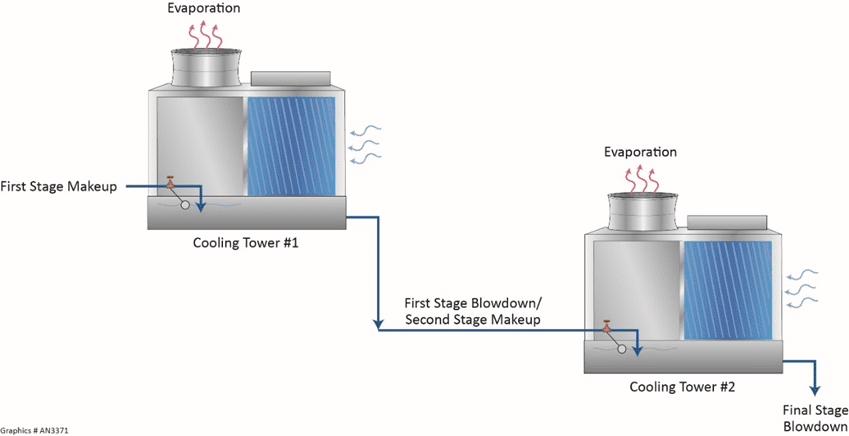

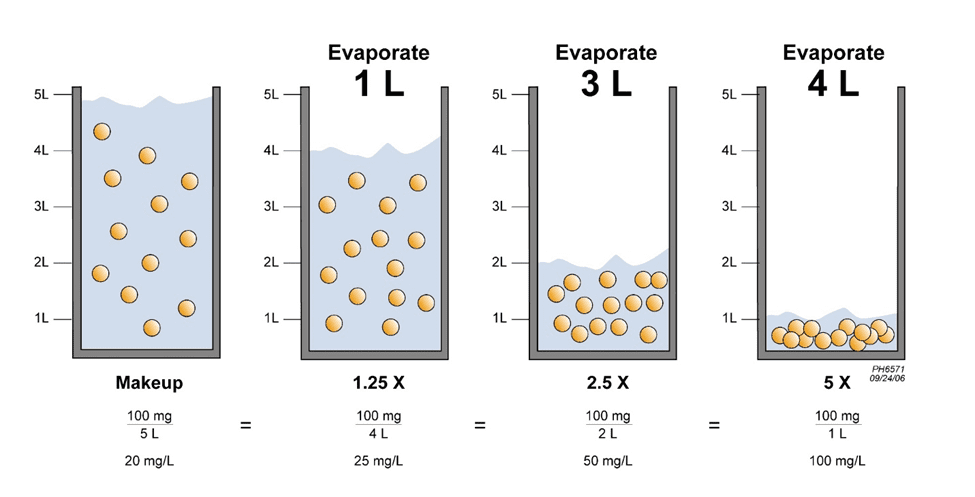

This graph depicts the relationship between the makeup water added to a cooling tower, discharged blowdown, evaporation, and cycles of concentration. The amount of evaporation depends on the amount of heat added to the cooling water by system processes. This heat is removed and ejected to the atmosphere outside. This is relatively constant as dictated by the heat expelled by the chiller to the water. Every pound of water evaporated through the tower removes nearly 1,000 Btu’s of heat.

The amount of makeup and blowdown water depends on the cycles of concentration, or how many times each volume of water is evaporated. In a once-through system, water passing through the tower is sent directly to the drain. These evaporative cooling towers consume the most amount of water. Without controlling blowdown, 1.25–1.50 cycles is the typical range. With some blowdown control, at 2 cycles of concentration, the makeup water requirement drops from 3,000 to 2,000 gpm, a reduction of over 30%. Savings further increase from 2 to 3 cycles with a 25% reduction; however, as the level approaches the constant volume of evaporated water (indicated by the blue line in the graph above), returns begin to diminish.

Increasing cycles can contribute to a higher mineral concentration as water evaporates, which can lead to scaling and fouling. These issues need to be controlled to maintain system efficiency.

HVAC Sustainability: Maintaining Equipment

At installation, new equipment runs at maximum efficiency. The goal of a good water treatment program is to maintain equipment in like-new, as-manufactured condition by keeping surfaces clean and mitigating corrosion and microbiological blooms. Fouling from dissolved minerals in makeup water can insulate heat transfer surfaces if not managed properly. Corrosion deposits on heat exchanger surfaces pose another risk, as does direct exchanger surface corrosion caused by heat flux. Corrosion products can insulate heat exchanger surfaces, impairing equipment performance while requiring greater energy to achieve the same degree of cooling.

Use of high-quality makeup water helps preserve equipment’s as-manufactured condition. Additionally, fouling potential must be balanced with the maximum degree of evaporation.

When seeking to improve sustainability, alternative sources of makeup water should be investigated to supplement and reduce the primary makeup source. A trained water treatment team can audit your water systems and come up with suggested sources of reuse water.

Why are Chemical Inhibitors Necessary?

Chemical inhibitors are used to mitigate the interrelated processes of corrosion deposition and biofouling from bacteria and algae or plant life. Corrosion can lead to deposition, and corrosion and deposition can both lead to biofouling. These issues will negatively impact system efficiency.

Conserve Energy by Maintaining Cleanliness

If you’re looking to conserve energy at your facility, keep the following in mind:

- Dirty systems are not as efficient as clean systems. They require more pumping water to achieve the same degree of cooling because the surfaces are not being cooled effectively. Fouling can also divert flow through the tower fill, insulate heat transfer, and put greater strain on system pumps.

- Mineral scale from makeup water and microbiological fouling may cause more energy to be consumed and prevent heat transfer and cooling.

- If fouled, heat exchangers can become large consumers of wasted energy.

- 1/16 inch of scale on heat exchanger surfaces in a 500-ton chiller could easily cause consumption of over $100,000 worth of energy compared to $80,000 if it were clean. This consumption is directly related to greenhouse gas emissions, which would increase proportionally.

| 500-Ton Chiller | Clean Condenser | Scaled Condenser |

| Electrical Costs | $80,000/year | $105,000/year |

| Water Use | 7,200,000 gallons/year | 7,200,000 gallons/year |

| CO2 Generation | 2,500,000 pounds/year | 3,310,000 pounds/year |

Water Resource Management

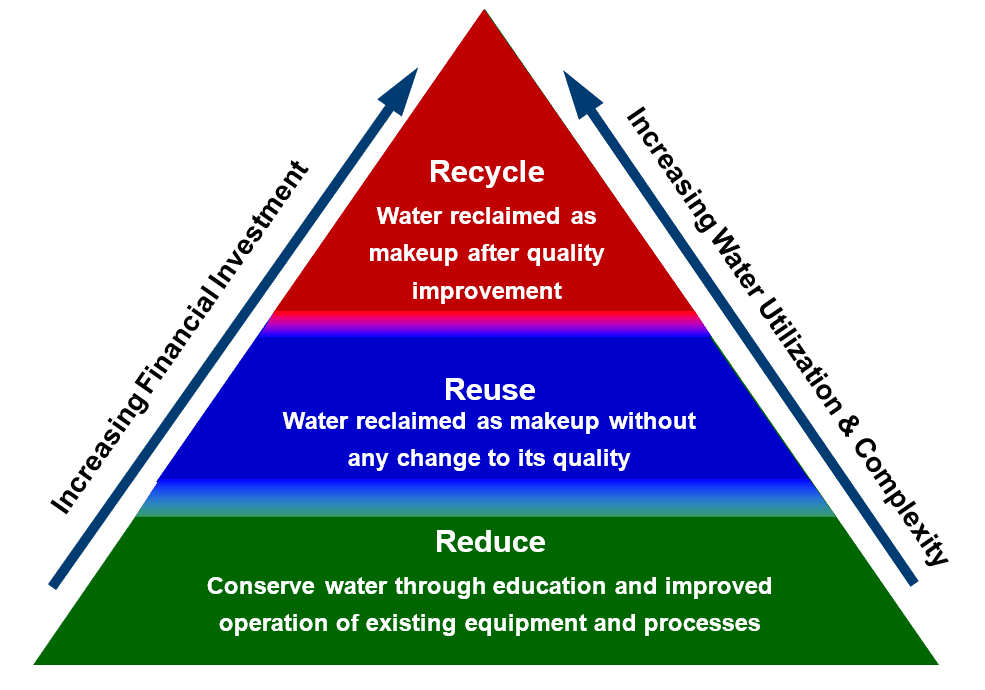

Recycling water entails treating streams of otherwise unsuitable water by investing in treatment and equipment to obtain high-quality water.

Reduce

The first step in reducing water usage is to ensure systems are operating at maximum efficiency. Strategies may include:

- Reviewing work practices to eliminate waste, immediately repairing any leaks

- Optimizing water source usages

- Improving equipment efficiency by increasing cycles of concentration for evaporative cooling

- Conserving water through education

Educating yourself on the operations and needs of your system is a vital step for effective water and energy reduction. This can consist of:

- Knowing the optimum setpoints for your cooling tower to prevent waste when the system is not operating at the maximum cycles of concentration based on the makeup water chemistry

- Maximizing boiler system cycles

- Cleaning fouled surfaces immediately to prevent energy impairment

- Mitigating equipment corrosion to prevent additional CO2 consumption associated with the manufacture and replacement of equipment and piping

- Maintaining system performance to minimize the need for remediation

- Although cleaning a fouled system with acid can be effective, it can also cause corrosion and impair equipment, wasting energy and water. It is best practice to maintain system cleanliness instead of waiting for fouling to occur before resolving system issues.

Reuse

Depending on its quality, some of the water used in your facility may be reused in other processes without requiring a heavy investment in pretreatment equipment.

Examine the quality of any water you may want to add to makeup streams. If the quality of the water is sufficient for reusing in other processes, you can install equipment to capture that water and plumb it to a usable location.

For example, boiler blowdown may replace city water in closed loops, eliminating boiler additions to the discharge stream and reducing costs.

Recycle

Cooling tower water is not reusable if a constituent in the water is at its maximum stable concentration, limiting additional cycling. A cooling tower operating efficiently will maximize the concentration of the minerals in the water. The resulting concentrated water can contribute to scaling when reused if not properly pretreated to remove dissolved solids.

Recycling saturated cooling tower water involves capturing effluent and installing equipment such as reverse osmosis (RO) systems or softeners to remove calcium and magnesium, the two primary components of scale formation caused by over-cycling.

Municipal Gray Water