The post Considerations for Complex Industrial Cooling Water Monitoring and Treatment appeared first on ChemTreat, Inc..

]]>This article was originally published in PPCHEM® Journal; PPCHEM® 2021, 23(5), 198–205; https://journal.ppchem.com/

Abstract

Heat exchangers are, of course, a critical component of power and heavy industrial plants. Many of these are water cooled, with the source being a cooling tower (commonly known as an open cooling system) or sometimes once-through cooling. Often, “closed” systems are also present, which are cooled by primary heat exchangers, but whose chemistry is significantly different from that of open systems. Successful chemical treatment of the wide variety of cooling systems in plants requires analysis of many factors, including the potential for corrosion, scaling, and microbiological fouling, system metallurgy, operating temperatures, and others, all of which are examined in this article. Also discussed are several significant improvements to chemical treatment programs in recent years, improvements that maintain proper heat transfer and reliability of cooling systems.

Introduction to Complex Industrial Cooling Water Monitoring and Treatment

At steam generating power plants, the primary water-cooled heat exchanger is the steam surface condenser, unless, of course, the plant has an air-cooled condenser (ACC). Several other heat exchangers are also present, including the turbine lube oil cooler, bearing cooling water heat exchanger, and the hydrogen cooler. Many additional heat exchangers are utilized at large industrial plants such as refineries, petrochemical plants, etc. A wide range of designs is possible: from shell-and-tube to plate-and-frame to jacketed systems and others. Cooling systems may be open or closed. These complex arrangements usually require a variety of treatment methods. Furthermore, unlike in modern power plants, where materials selection has gravitated towards all-ferrous metallurgy throughout the condensate, feedwater/economizer, and boilers, several metals may be present in industrial systems. Copper alloys are quite common as the tube material in shell-and-tube heat exchangers.

Factors Affecting Cooling System Performance

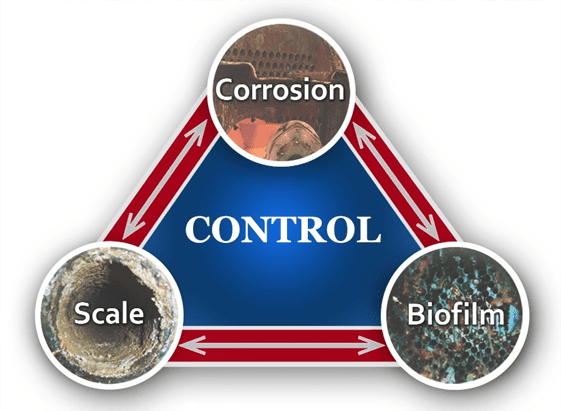

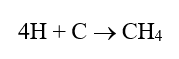

Many factors can influence cooling system and heat exchanger performance and reliability, with a general representation outlined in Figure 1.

Figure 1. The corrosion-deposition-biofouling triangle.

As this diagram suggests, corrosion, scale formation, and biological fouling are not individually exclusive. A plant’s chemical treatment program needs to account for all three factors, and indeed the triangle could even be expanded to include environmental issues [1]. In the first portion of this article, we will focus on open systems, and primarily those supplied from cooling towers.

Open Cooling Systems

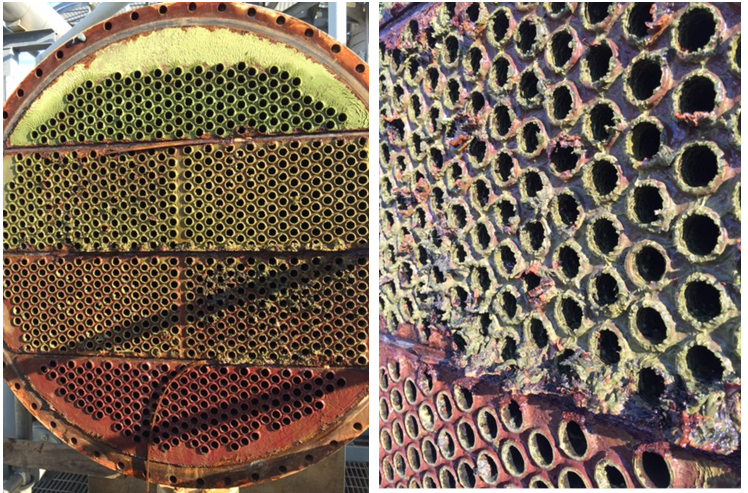

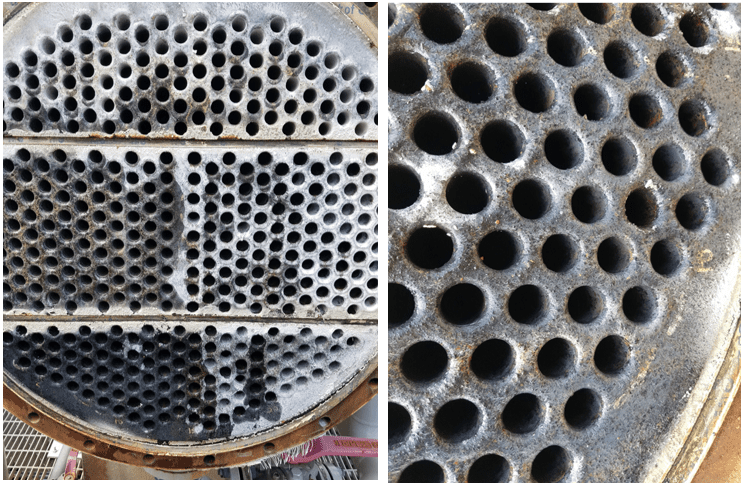

A classic example of concurrent issues can be seen in Figure 2, which shows a multi-pass tube-and-shell heat exchanger, whose cooling water at the time was treated with a traditional phosphate-based program.

Figure 2. Multi-pass heat exchanger on a phosphate program just prior to a change in treatment chemistry.

At the inlet end of the heat exchanger (the tubes on the bottom of this unit), corrosion was problematic. At the warmer outlet side (on the top), deposition and scale formation was occurring. Thus, the program was not particularly effective at mitigating corrosion or deposition depending on location. We will return to this example later in the article.

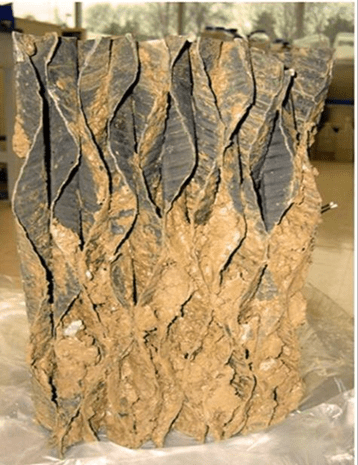

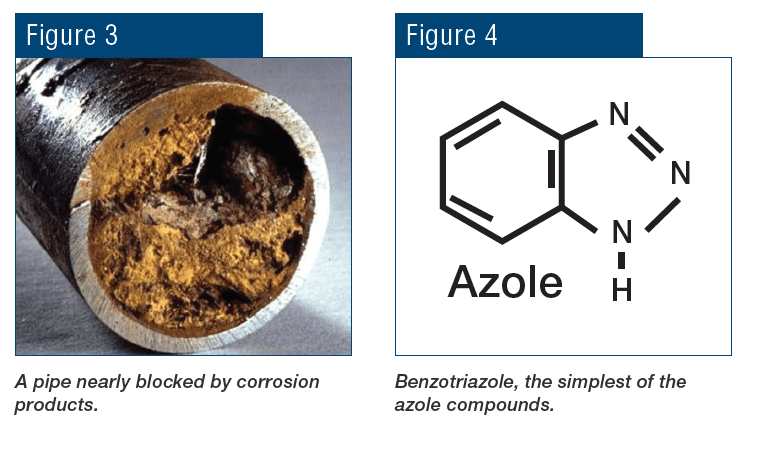

From a microbiological perspective, cooling systems provide an ideal environment, warm and wet, for microbes to proliferate and form colonies. Bacteria can grow in heat exchangers and cooling tower fill, fungi on and in cooling tower wood, and algae on wetted cooling tower components exposed to sunlight. A major problem with microbes, particularly some bacteria, is that once they settle on surfaces, the organisms secrete a polysaccharide layer (slime) for protection. This film can severely inhibit heat transfer, and it can also collect silt from the water and grow thicker, further degrading heat exchange (see Figure 3). Biofilms restrict heat transfer more effectively than almost any other deposit. Furthermore, heavy fouling can drastically reduce fluid flow, sometimes to the point of complete blockage.

Figure 3. Heat exchanger tubes fouled with microbes and slime.

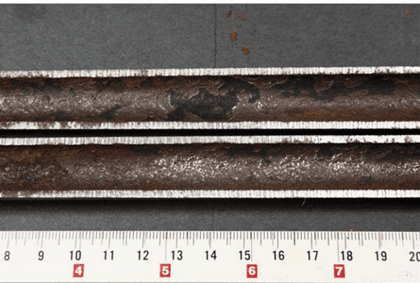

In another nod to Figure 1, the protective slime layer formed by initial bacterial deposits allows anaerobic and facultative bacteria underneath to flourish. These organisms can generate acids and other harmful compounds that directly attack metals. Microbial deposits also establish concentration cells, where the lack of oxygen underneath the deposit causes these locations to become anodic to other areas of exposed metal. Metal loss occurs at the anodes, with pitting as the result (see Figure 4).

Figure 4. A large under-deposit corrosion pit (with deposit removed) in a stainless steel heat exchanger tube.

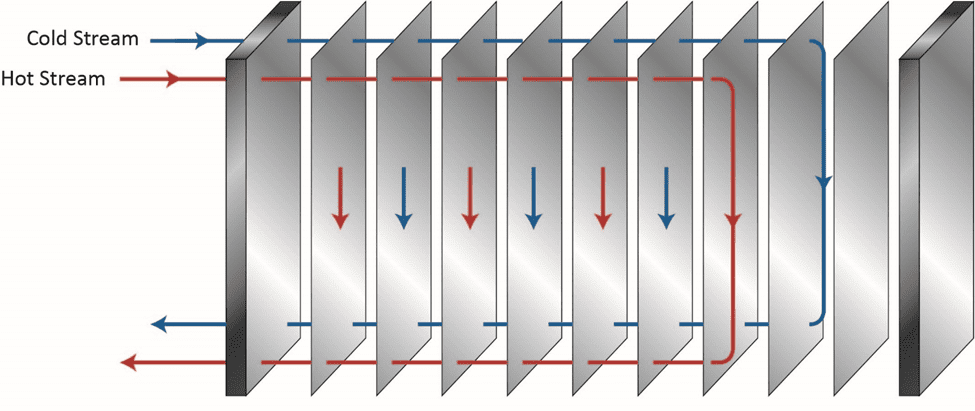

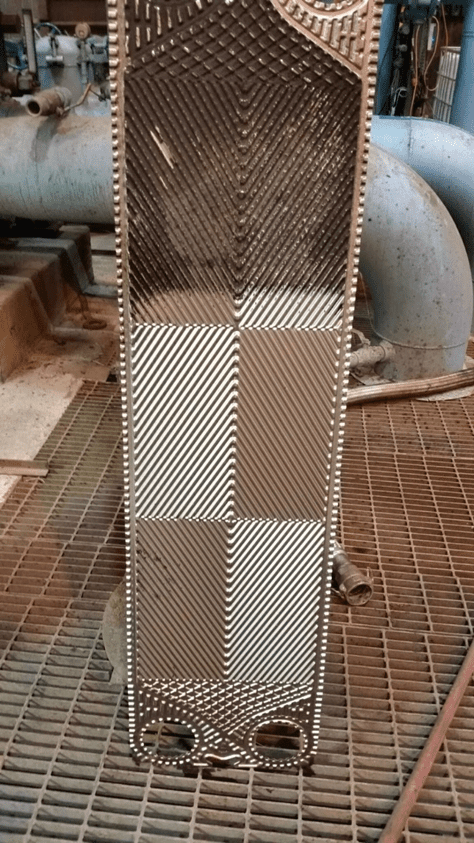

Of course, proper chemistry control to minimize fouling and scaling is a key method to help maintain heat exchanger reliability and performance, as we will explore later, but a benefit of the shell-and-tube design over others is the ability, in many cases, to remove slimy deposits and some hardness compounds by mechanical cleaning. Mechanical cleaning of other heat exchangers, for example plate-and-frame units (Figures 5a b), can be much more difficult, if not impossible.

Figure 5a. Basic flow diagram of a single-pass plate-and-frame heat exchanger.

Figure 5b. An individual plate from a plate-and-frame heat exchanger. Lower part of the plate already cleaned by water jet washing, upper part uncleaned, exhibiting fouling that reduced heat transfer.

The narrow spacing between the plates offers a prime setup for fouling and deposition, and as Figure 5b illustrates, the plates are often designed with a corrugated or similar pattern to enhance fluid turbulence and heat transfer. Even so, fouling and deposition cannot be hindered completely.

Another very important aspect of corrosion/deposition issues in heat exchangers is the wall surface, also known as the skin, temperature. While the general increase in bulk cooling water temperature as the water passes through a heat exchanger can influence many reactions, additional or more pronounced reactions are possible at the metal surface, where temperatures may be significantly higher than in the bulk water. This is a factor to consider when evaluating heat exchanger design, metallurgy, and chemical treatment programs.

Don’t Forget the Cooling Towers

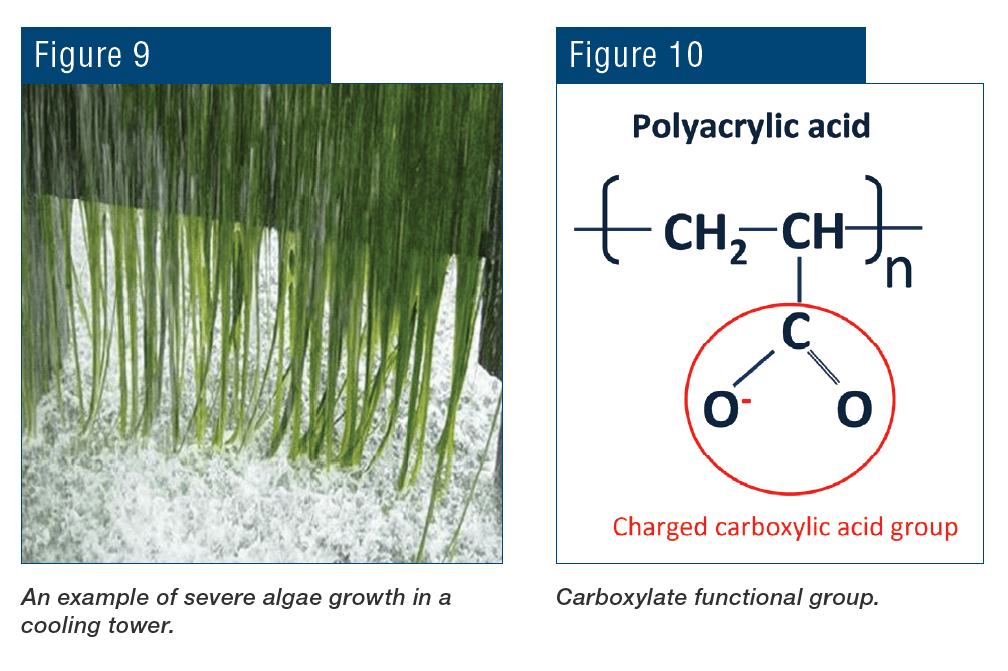

Cooling towers are another set of heat exchangers susceptible to corrosion, scaling, and especially fouling. Figure 6a shows cooling tower fill with heavy fouling. In Figure 6b, long algae threads hang from the fill to nearly the cooling tower basin.

Figure 6a. Fouled cooling tower film fill.

Figure 6b. Severe algae growth in a cooling tower.

Control Techniques

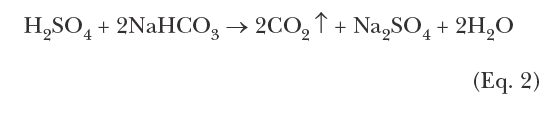

Treatment methods for controlling the “big three” issues of the Figure 1 triangle have been addressed by the authors in a previous article for this journal [2]. To recap: During the middle of the last century, chromate (CrO42-) coupled with sulfuric acid feed was very popular for corrosion and scale control in many cooling systems. While chromate is considered an anodic inhibitor, with sufficient dosage, it will form a complete surface layer of iron chromate (pseudo-stainless steel), which can be quite protective. Acid feed to maintain a cooling water pH within a 6.5–7.0 range converts much of the bicarbonate ion (HCO3–) alkalinity to CO2, which escapes as a gas. Reduction of alkalinity greatly reduces the potential for calcium carbonate (CaCO3) scaling, which is typically the first mineral deposit that would otherwise precipitate without treatment. Chromate/acid chemistry is very straightforward and effective; however, environmental issues related to chromium discharge, particularly with respect to the toxicity of hexavalent chromium (Cr6+), led to abandonment of this method.

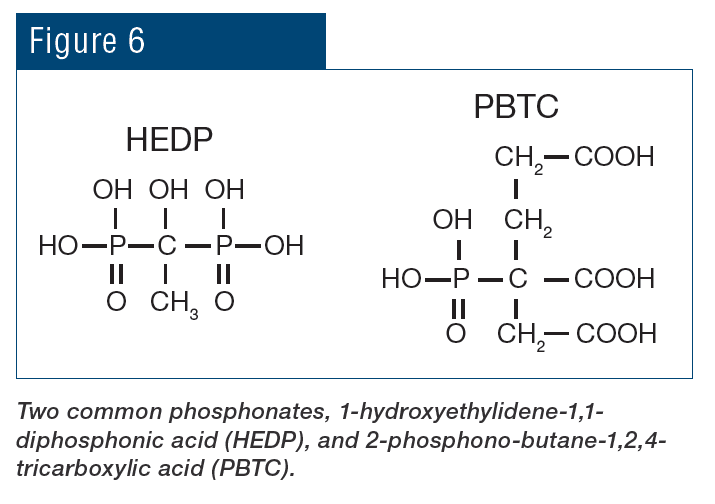

Treatment then evolved to phosphate-based chemistry for both scale and corrosion prevention. These programs typically function at a mildly alkaline pH range of approximately 8.0–8.5, which minimizes general corrosion. The chemistry also provides additional corrosion protection, as phosphate will react with ferrous ions (Fe2+) produced at anodic sites to form a reaction-limiting deposit, while calcium phosphate (Ca3(PO4)2) precipitates in the local alkaline environment at cathodic sites to inhibit electron transfer. However, even small upsets in phosphate programs can cause severe calcium phosphate fouling, and at one time, Ca3(PO4)2 deposition became almost as great a problem as calcium carbonate scaling had been before. Treatment methods evolved to more forgiving methodologies, with organic phosphate (also known as phosphonate) as the backbone in many cases, supplemented with polymer for calcium phosphate deposition control. Phosphonates attach to deposits as they are forming and disrupt crystal growth and lattice strength.

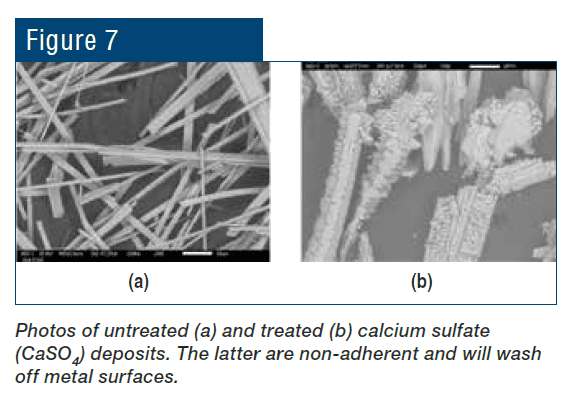

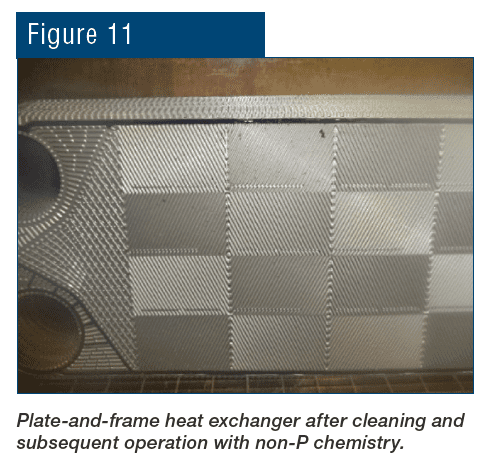

Even with these improvements, many problematic issues remain with phosphate/phosphonate treatment, including increasing concern about phosphorus discharge to the environment. These issues have led to advanced methodologies with the core functionality based on reactive polyhydroxy starch inhibitor (RPSI) chemistry as exemplified by, for example, ChemTreat’s FlexPro® technology. By virtue of many active sites on the molecules, these compounds attach to the base metal and form a protective layer. Common RPSI formulations also include advanced polymers that inhibit scale formation by crystal modification and ion sequestration. Figure 7 shows the same heat exchanger from Figure 2 following cleaning and changeover to FlexPro® treatment.

Figure 7. The heat exchanger from Figure 2 on FlexPro® chemistry. Tubes are essentially free of corrosion and deposition.

Most modern cooling tower chemical treatment programs operate in a mildly basic pH range of 8.0–8.5. Chlorine gas was the workhorse for microbiological treatment for many years, although liquid bleach (NaOCl) feed supplanted gaseous chlorine at many plants for safety reasons. When chlorine is added to water, the following reaction (Eq. (1)) occurs:

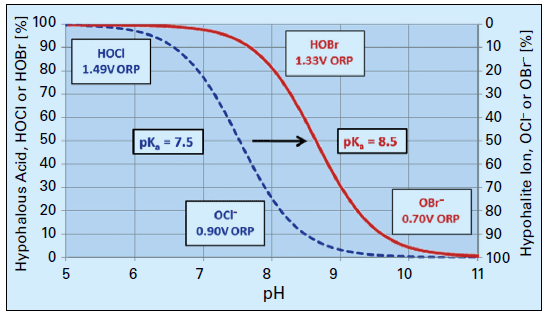

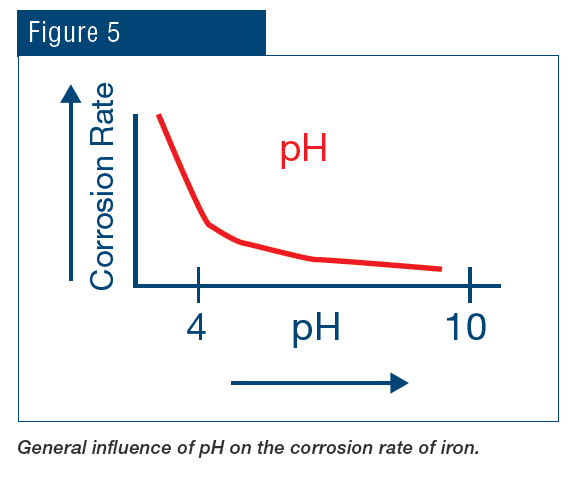

Hypochlorous acid (HOCl) is the killing agent, and it functions by penetrating cell walls and oxidizing internal cell components. The efficacy and killing power of this compound are greatly affected by pH because of the equilibrium nature of HOCl in water, as shown in Eq. (2).

OCl– is a much weaker biocide than HOCl, probably because the charge on the OCl– ion does not allow it to effectively penetrate cell walls. The dissociation of hypochlorous acid dramatically increases as the pH rises above 7.5. Because many cooling tower scale/corrosion treatment programs operate at an alkaline pH, chlorine chemistry may not be the best choice for some applications. Chlorine efficiency is further influenced by ammonia and organics in the water, which react irreversibly with the chemical and increase chlorine demand.

A popular solution to this difficulty has been bromine chemistry, where a chlorine oxidizer (bleach is the common choice) and sodium bromide (NaBr) are blended in a makeup water stream and injected into the cooling water. This chemistry produces hypobromous acid (HOBr), which has similar killing powers to HOCl but functions more effectively at an alkaline pH. Figure 8 compares the dissociation of HOCl and HOBr as a function of pH.

Figure 8. Dissociation of HOCl and HOBr vs. pH.

Many facilities such as refineries, chemical plants, steel and paper mills, food and beverage plants, etc., often have cooling systems with waters containing elevated organics, nitrogen species, or other impurities that severely inhibit the performance of conventional oxidizers. Accordingly, ChemTreat researchers have improved upon and developed alternative oxidizing biocides that may perform much more effectively in difficult cooling waters. One is monochloramine (NH2Cl) with precise generation for each application. This compound is a weaker oxidizer than chlorine or bromine, but research and operating experience show the chemical to be more effective than chlorine or bromine at penetrating the protective bacterial slime layer that consumes stronger oxidants.

Another option is a specialty solution of chlorine dioxide (ClO2). This compound is a selective oxidizer, but even though it is chlorine-based, it does not react with ammonia and reacts less vigorously with some organics than chlorine. Furthermore, the compound is not influenced by pH. On-site chlorine dioxide generation is required, as large quantities of chlorine dioxide cannot be safely stored in containers or tanks. However, most modern production methods include more safeguards and safety checks than past technologies.

For those plant personnel who still wish to use bleach (sodium hypochlorite), but whose cooling systems face at least some of the challenges mentioned above, the use of halogen stabilizers may be a good choice. These products typically contain a combination of halogen stabilizer and bio-penetrant. The former, as its name implies, stabilizes the chlorine in solution and provides a controlled release. The bio-penetrant aids biocide efficacy by destabilizing protective slime layers to allow the oxidizer better access to the underlying organisms.

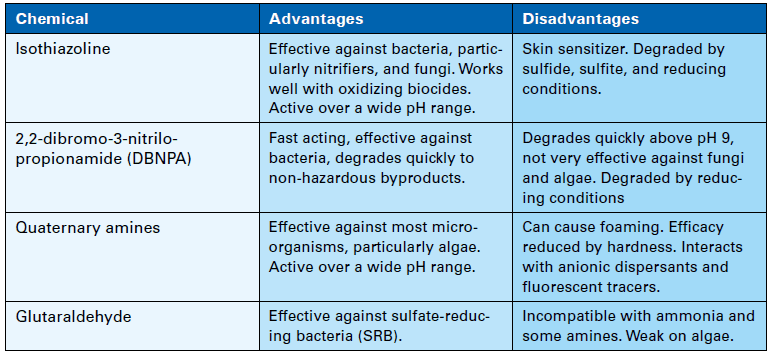

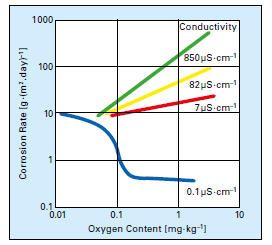

At some plants, oxidizer feed is limited to two hours per day, which gives microbes time to settle and form colonies during off times. Accordingly, a supplemental feed of nonoxidizing biocide on perhaps a once-per-week basis can be quite effective in controlling biological growth. Nonoxidizers in conjunction with bio-penetrants reduce overall chlorine usage and do not produce halogenated organic byproducts. Table 1 below lists properties of some of the most common nonoxidizers.

Table 1. Nonoxidizing biocides.

Careful evaluation of the microbial species in the cooling water is necessary to determine the most effective biocides. Antimicrobial compounds should not be used or even tested without approval from the appropriate regulating agency. They must be incorporated into the plant’s discharge permit. Also, as with all chemicals, safety is an absolutely critical issue with biocides. Safety Data Sheet (SDS) guidelines should be followed to the letter when handling these products.

Closed Cooling Water (CCW) Treatment

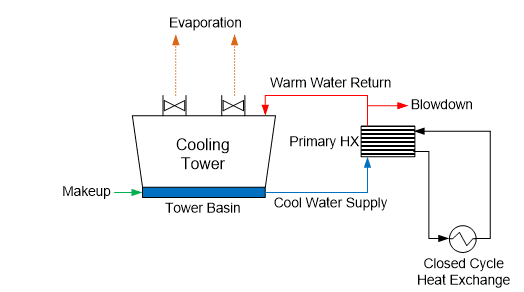

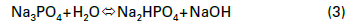

Many plants have numerous heat exchangers that are usually embedded in a closed cooling water system, which rejects heat to the primary open recirculation cooling system (see Figure 9).

Figure 9. General schematic of a primary open-recirculating and secondary closed cooling system arrangement.

The term “closed” cooling water system is somewhat of a misnomer, as virtually all systems have leaks or small losses somewhere that require makeup. (If serious corrosion has occurred, these losses may be significant.) Systems are often designed with a head tank for water makeup and handling changes in demand. This arrangement can allow some oxygen to enter the cooling water, which, of course, influences the corrosion potential.

While it may be possible to utilize water with varying qualities in CCW systems, a common choice, and our main focus here, is specially-treated condensate or demineralized water. Choosing condensate over less pure water minimizes the possibility of difficulties from scale-forming hardness compounds or corrosive agents such as chloride and sulfate.

A typical piping material for CCW systems is carbon steel, with stainless steel or perhaps copper alloys being a common choice for heat exchanger tubes or plates in plate-and-frame exchangers. Other metals may include aluminum or those metals contained in the solder of fittings within heat exchanger cooling coils. When planning a treatment program, it is important to know the entire system metallurgy.

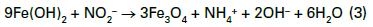

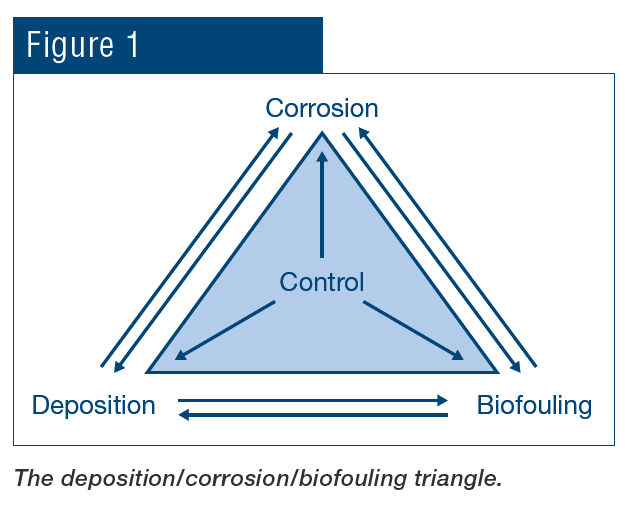

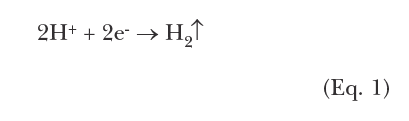

Corrosion inhibitors slow reactions at either the anode, the cathode, or sometimes both sites of electrochemical cells. A very common treatment method, based on cost and ability to protect carbon steel, is nitrite applied via injection of sodium nitrite (NaNO2) to the cooling circuit. When carbon steel is first placed into service, the metal surface develops an oxide layer. While formation of this oxide coating is a corrosion mechanism, the layer serves as a protective film for the base metal underneath. However, the natural oxide layer can be damaged by mechanical influences or penetrated by corrosive agents. Nitrite forms a passivating iron oxide film at anodes that can eventually cover the entire steel surface. A representative reaction of this chemistry is outlined in Eq. (3).

An important aspect to be noted from this equation is that the nitrite reaction produces ammonia, which can induce corrosion of copper alloys, particularly if an oxidizing element or compound such as oxygen is also present in the water. The pH of these solutions is typically adjusted to a range of 8.5–11 with an alkaline compound such as sodium hydroxide or the buffering agent sodium tetraborate, commonly known as borax.

A key concept with regard to anodic inhibitors such as nitrite is that the chemical concentration should not be allowed to fall below a minimum value. If the level drops too low, anodes will develop in what is otherwise a large cathodic environment, establishing localized sites for very intense corrosion. Through-wall pitting may be the result. A common range for nitrite concentration is 500–1,500 mg∙L-1. The authors have worked with closed cooling systems in which this range could not be maintained because of significant leaks. Treatment was suspended to protect the remainder of the piping from localized corrosion. The proper response to such issues is repairing and replacing corroded piping to return the system to “closed” status. Plant management may not always agree with this philosophy because of the cost and complexity of the task. However, large leakage requires large makeup. Excessive feed of oxygen-saturated makeup propagates corrosion.

One disadvantage of nitrite treatment is that the chemical serves as a nutrient for certain bacteria, such as Nitrobactera Agillis, which converts nitrite into nitrate (NO3–), which, in turn, can generate significant slime. Author Brad Buecker once observed a nitrite-treated closed cooling water system at a large automobile assembly plant, in which microbial slime restricted flow in the small-bore cooling coils of automated welding devices. Overheating became a problem. Also, some microorganisms, via their metabolic processes, produce acids and other harmful byproducts that can directly attack metals via the mechanism known as microbiologically-induced corrosion (MIC).

Another corrosion inhibitor option, albeit a more expensive one, is molybdate (MoO42-), which is generated by the addition of sodium molybdate (Na2MoO4) to the cooling water. Like chromate, molybdate binds with iron to form a surface layer of ferrous molybdate (FeMoO4). This compound provides good protection, particularly against the harmful anions chloride and sulfate. A common dosage range is 200–1000 mg∙L-1, with a typical recommended pH range of 9.0–11.0. Nitrite and chromate can be blended to provide a synergistic effect, where the nitrite enhances tighter molybdate bonding. Often in these cases, the control range for each chemical is slightly lower than if utilized individually.

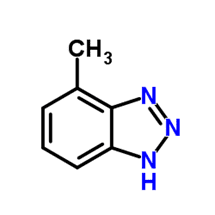

Other protection methods are available, including protection by silicates, and the use of a reducing agent such as hydrazine to maintain the passive Fe3O4 (magnetite) layer on carbon steel and cuprous oxide (Cu2O) on copper alloys. However, for copper alloys, azole chemistry is often the best choice. A common member of the azole group is tolyltriazole (TTA), whose structure is shown in Figure 10.

Figure 10. Basic structure of TTA.

When utilized in basic solutions, which is common for nitrite and molybdate, the molecule deprotonates (loses the hydrogen ion), and nitrogen bonds to the copper surface. The organic rings of the compound form a plate-like film to protect the base metal.

CCW Microbiological Control

In a closed system with no organic loading, the conditions are theoretically unfavorable for microbiological fouling. Yet, as has already been noted, fouling can be problematic in some systems, and particularly those that use some form of organic chemicals, e.g., azoles or dispersants, which can break down and provide food for microbes. Add a nutrient such as nitrite, or its reaction product, nitrate, and significant problems may arise. If the system utilizes water other than condensate, other microbes such as sulfate-reducing bacteria may proliferate.

Therefore, microbiological treatment may be necessary, but unlike open cooling systems, oxidizing biocides are typically not utilized in closed systems. Oxidizers can react with some corrosion inhibitors such as nitrite or introduce corrosive species, e.g., chloride, to the water. Nonoxidizing biocides are the preferred choice, some of which have already been discussed above for open systems.

Conclusion

Large industrial plants typically have numerous heat exchangers, usually of many different sizes, designs, and metallurgies. A “one-size-fits-all” chemistry program will not work for these complex arrangements, and a thorough analysis of each system is appropriate for optimizing chemical treatment programs. Included in the heat exchanger list are cooling towers, which often sit in far corners of the plant or on top of buildings, where minimal attention is often paid until an upset occurs.

Of course, each system is different and has unique treatment needs, and due diligence is necessary for determining the feasibility for utilizing these methods. Always consult your equipment manuals and guides and contact a water treatment professional before making changes to your systems and treatment processes.

References

1. Buecker, B., “Environmental Considerations in the Advancement of Cooling Treatment Technology”, Water Technology 2021, 44(3). Available from https://www.watertechonline.com.

2. Post, R. M., Kalakodimi, R. P., and Buecker, B., “An Evolution in Cooling Water Treatment”, PowerPlant Chemistry Journal 2018, 20(6), 346.

The Authors

Brad Buecker (B.S., Chemistry, Iowa State University, Ames, IA, USA) is a Senior Technical Publicist with ChemTreat. He has many years of experience in or affiliated with the power industry, much of it in steam generation chemistry, water treatment, air quality control, and results engineering positions with City Water, Light & Power (Springfield, IL, USA) and the Kansas City Power & Light Company’s (now Evergy) La Cygne, KS, USA, generating station. He also spent two years at a chemical manufacturing plant and an additional 11 years at two engineering firms. He is a member of the ACS, AIChE, ASME, AIST, AMPP (NACE), the Electric Utility Chemistry Workshop planning committee, and the Power-Gen International planning committee. Mr. Buecker has authored many articles and three books on power plant topics.

Prasad Kalakodimi (M.S., Physical Chemistry, Andhra University, Andhra Pradesh, India, Ph.D., Electrochemistry, Indian Institute of Science, Bangalore, India) received his Ph.D. in 2003. Dr. Kalakodimi is currently the Director of Applied Technology for ChemTreat, Inc., in Glen Allen, VA. Prior to joining ChemTreat, Dr. Kalakodimi served as the engineering technical leader at the GE India Technology Centre in Bangalore and as product manager for chemicals and monitoring solutions for GE Water. He has over 20 patent filings, 20 international publications, and various conference presentations.

Contact us to learn more and request a consultation.

The post Considerations for Complex Industrial Cooling Water Monitoring and Treatment appeared first on ChemTreat, Inc..

]]>The post Monitoring Industrial Plant Discharge Metals and TOC appeared first on ChemTreat, Inc..

]]>This article was originally published in PPCHEM® Journal; PPCHEM® 2021, 23(4), 152–157; https://journal.ppchem.com/

Abstract

Industrial facilities such as refineries, petrochemical plants, steel mills, metal finishing facilities, pulp and paper mills, pharmaceutical plants, etc. require substantial wastewater treatment, as some processes at these facilities can release many complex carbon compounds or other toxic constituents, including metals, to waste streams.

While various techniques are available for measuring trace level metals in process water, to date they have been rather unavailable to many industrial locations because of capital cost requirements or the need for specially trained technicians. Two well-known techniques are inductively-coupled plasma and atomic absorption spectroscopy, which need specially trained operators and require complex sample preparation and expensive instrumentation.

This article discusses another existing technology, colorimetry, which has been modified for on-line monitoring. The method is suitable for many facilities and can be operated by a wide range of plant personnel. In many cases, the readings can be enhanced with TOC analyses to provide additional protection for industrial water/steam systems.

Introduction to Monitoring Industrial Plant Discharge Metals and TOC

When author Brad Buecker began a lengthy career in the coal-fired power industry four decades ago, common discharge regulations for US power plants focused on four impurities or parameters: total suspended solids (TSS), pH, oil and grease (O&G), and residual oxidizing biocide concentration. These days, it is well recognized that many other wastewater impurities can cause problems for power producers. Of course, facilities such as refineries and petrochemical plants require substantial wastewater treatment, as refining and organic chemical synthesis can release many complex carbon compounds and toxic constituents to waste streams. Many other heavy industries such as steel mills, metal finishing facilities, pulp and paper mills, and pharmaceutical plants also deal with challenging wastewater treatment issues.

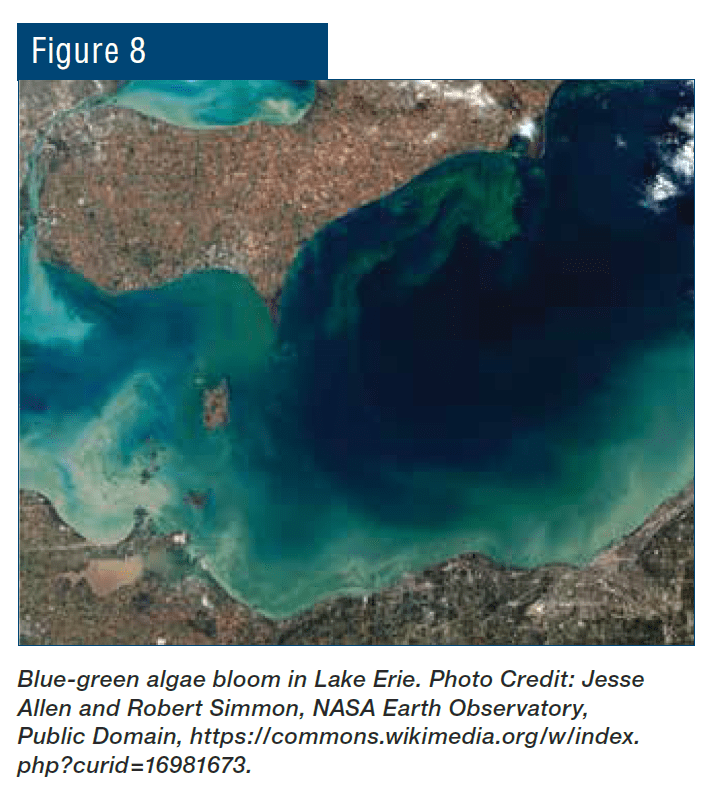

Along with these applications, discharges from other seemingly benign processes (e.g., cooling tower blowdown and storm water runoff) are facing increased regulation because of their potential negative effects on the natural environment. A well-known example is tighter regulation of phosphorus in cooling tower discharge, which was previously reported in this journal [1]. Ammonia is another impurity of concern; like phosphorus, it is a prime nutrient for the large algae blooms that have plagued many surface water bodies. New technologies that minimize or eliminate inorganic and organic phosphates for cooling tower water treatment have become very popular.

However, concern continues to grow over discharges containing transition and heavy metals, as well as metalloids. These constituents include zinc, copper, chromium, selenium, arsenic, and others. The ability to monitor trace concentrations of metals is important for plant operators and technical staff when evaluating the efficacy of treatment programs and ensuring compliance with discharge guidelines.

Metals of Concern and a Review of Some Treatment Techniques

While trace concentrations of some heavy metals are important for certain biological functions, others pose a significant danger to the environment and sometimes even to internal plant processes. Antimony, selenium, and arsenic are highly toxic even at very low levels. Chromium, arsenic, cadmium, mercury, and lead have a strong affinity for sulfur, and can bond to enzymes in the human body, inhibiting metabolic reactions. Arsenic, hexavalent chromium, manganese, and cobalt are carcinogens. Cadmium causes a degenerative bone disease. Mercury, lead, and manganese can damage the central nervous system. From an industrial perspective, manganese, aluminum, and iron can cause deposition and corrosion problems in plant process and cooling water systems. This list is not exhaustive, but it offers an indication of how serious the negative impacts of many metals can be [2-4].

Of course, much R&D has gone into treatment technologies for metals removal from process and wastewater streams. We will discuss several techniques before moving to the monitoring portion of this article. Perhaps somewhat surprisingly, many modern treatment methods do not rely on exotic equipment but have resulted from chemistry improvements within traditional processes. Consider the CoMag® ballasted clarification process [5]. Ballasted clarification has become popular, as these units operate with high rise rates, which, in turn, allow for clarifier design with much smaller footprints than conventional equipment. The original material for many ballasted clarifiers was micro-sand, which works well for providing a dense material to capture floc and improve settling. However, this precipitation process utilizes magnetite (Fe3O4) ballast. As with micro-sand, magnetite offers a dense substrate for settling enhancement, but with a significant advantage in that several heavy metals will co-precipitate with the iron and depart the system within the clarifier sludge. These trace metals or metalloids include copper, aluminum, and arsenic.

Another chemistry advancement relies on the aforementioned affinity of sulfur for certain metals. A leading example is mercury, which binds quite strongly with sulfur. Water treatment polymers with active sulfur sites have been developed for blending with other flocculating agents in standard clarifiers. These polymers can be quite effective for mercury removal, but sometimes the reaction is so fast that it generates very fine flocs. Care may be necessary to prevent the fine flocs from escaping with the clarifier overflow.

Another problematic impurity for several industries is selenium. Selenium is a naturally occurring element that, in power plant coal combustion, is typically released in two species, selenite (SeO3) and selenate (SeO4). These oxides are captured in ash sluicing or wet flue gas desulfurization (WFGD) streams. For years, the best available technology (BAT) for selenium removal, as determined by the United States Environmental Protection Agency, has been biological treatment per adsorption of the oxidized selenium compounds on an organic substrate, and subsequent digestion of the selenium oxides by microorganisms that convert the compounds to elemental selenium retained by the microbes. These systems are very large, expensive, and require periodic removal of spent organisms and replenishment of the microbiological substrates.

ChemTreat now offers SeQuester , which is a physical-chemical alternative to biological selenium removal. The process utilizes co-precipitation chemistry and pH adjustment to capture selenium in conventional wastewater treatment equipment such as clarifiers, holding tanks, and filter presses. The configuration can be designed to treat not only direct discharge from wet scrubbers, but also stored ash pond water, collected landfill leachate, and mine tailing discharges, all at potentially much lower cost than the current BAT methods. Furthermore, pilot test results indicate the technology may lower the concentrations of other trace metals, including arsenic, cadmium, chromium, lead, mercury, and silver [6].

, which is a physical-chemical alternative to biological selenium removal. The process utilizes co-precipitation chemistry and pH adjustment to capture selenium in conventional wastewater treatment equipment such as clarifiers, holding tanks, and filter presses. The configuration can be designed to treat not only direct discharge from wet scrubbers, but also stored ash pond water, collected landfill leachate, and mine tailing discharges, all at potentially much lower cost than the current BAT methods. Furthermore, pilot test results indicate the technology may lower the concentrations of other trace metals, including arsenic, cadmium, chromium, lead, mercury, and silver [6].

Many coal plants, both operating and shuttered, are also struggling with environmental edicts to close ash ponds. Several well-publicized accidents have released large quantities of ash and water into the environment. Since pond remediation does not allow for the water to be directly drained to some other receiving body of water such as a river or lake, rigorous treatment may be necessary before ponds can be drained and closed.

A critical aspect to successful removal of impurities from wastewater streams is accurate monitoring of the contaminants, which brings us to the second section of this article.

Detection and Monitoring Methods for Metal Concentrations

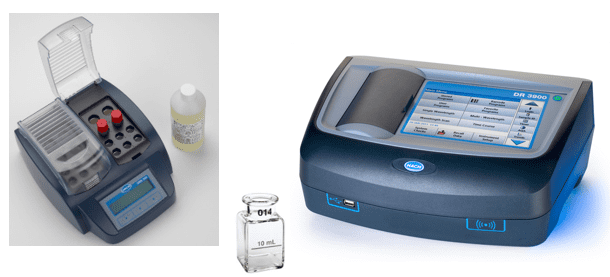

We will now examine an existing and somewhat familiar technique for metals monitoring. The colorimetric method, with an option for digestion to determine both dissolved and total concentrations, has been adapted for on-line trace metal analysis.

Various criteria exist for categorizing metals. Generally, heavy metals are those that have a density greater than 5g ⋅ cm–3. This is the criterion selected for this discussion, even though other metals or metalloids such as aluminum and selenium may be of concern in various processes despite not formally fitting into this category [7]. Often, the transition metals are lumped in with heavier metals when it comes to certain properties.

A variety of technologies are currently available for monitoring trace metal concentrations. However, many methods only offer snapshot analyses of a sample obtained from the process stream of concern. Two well-known techniques are inductively-coupled plasma (ICP) and atomic absorption spectroscopy (AAS), which need specially trained operators and require complex sample preparation and expensive instrumentation.

Such methods may be acceptable when the water sample is not expected to change over short periods of time, e.g., 24 hours. However, in many process streams, upsets or deviations may frequently occur because of changes in some aspect of the overall process. In any of these instances, some type of on-line or continuous monitoring is needed for accurate evaluation of process conditions.

Before moving forward with this discussion, it is important to set forth some qualifications. Colorimetry requires a relatively clean sample, which may preclude the use of this technique in some industrial settings. In general, maximum particle size should be less than 100μm, at a concentration of less than 0.1g ⋅ L–1 and a turbidity (measured as nephelometric turbidity unit, NTU) of less than 50NTU. Total organic carbon (TOC) should be less than 25mg ⋅ L–1. These are meant to be guidelines only and not a guarantee of performance. Sample dilution, either internal to the analyzer or external, may be an option, including when color is present. Filtering is also possible for samples with suspended solids, but consideration should be given to whether the particles being removed contain any of the substances being measured. This being stated, the analytical method will now be described.

Metal Analysis Using Colorimetry

Many power plant and industrial chemists have utilized colorimetric techniques for years to track water/steam chemistry. Common parameters include phosphate, silica, and ammonia, with the technology having long ago advanced beyond grab sample measurements to continuous on-line analyses. In fact, applications for continuous phosphate monitoring continue to evolve. One example of this evolution is the increasing selection of reclaimed municipal wastewater as makeup supply for industrial plants. Accurate analyses of inlet phosphate concentrations are important for controlling cooling water treatment programs and other processes.

Grab sample colorimetric analysis for metals has also been a viable method for decades, but adapting colorimetry for on-line monitoring requires additional consideration. This can be accomplished using software-controlled valves that introduce the required reagents at the appropriate time.

The metals that can currently be analyzed with colorimetry are chromium, manganese, iron, nickel, copper, and zinc. While not considered as heavy metals, aluminum and boron, which have been shown to be detrimental to health and the environment at certain levels, can also be measured using this technique.

For those metals that exist as suspended particles, digestion is required to convert them to a dissolved state. Generally, this is accomplished via acid addition and heating to 120°C for a minimum of 10min. This step is performed in a separate digestion vessel per Figure 1. The sample is then cooled, transferred to the analysis vessel, and subjected to an initial absorbance reading taken before reagent addition. The proper analytical wavelength will conform to the specific metal and reagent combination responsible for the color development. The final absorbance is then measured after reaction of the reagent with the metal, with final calculation per Beer’s Law.

Figure 1: Digestion unit.

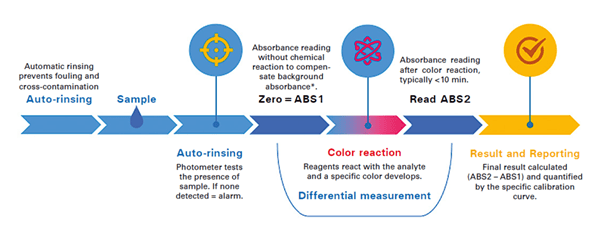

This method is summarized in Figure 2, and the correct chemical reagents vary depending on the metal to be analyzed. For example, adding ethylene-diamine-tetraacetic acid (EDTA) and a reducing reagent minimizes interferences when analyzing zinc or manganese. Some interference may still occur if the sample has large amounts of color, turbidity, and significant concentrations (mg⋅L–1 levels) of certain other metals.

Figure 2: The colorimetric cycle. *If additional buffer is added, ABS1 is only read after addition of this buffer

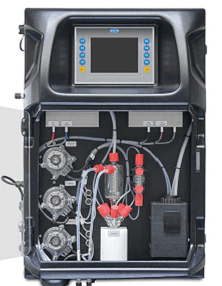

It should be noted that although colorimetry has evolved into an on-line method, the analyses themselves are batch reactions. Depending on the metal and whether or not a digestion is required, analysis times can range from 10 to 30 minutes. While the use of an integrated sequencer can permit the analysis of up to 8 individual streams, the number of discreet readings per stream is reduced accordingly (e.g. with a 10-minute cycle time and 6 streams, only 1 reading per stream is reported per hour). A typical instrument with software-controlled valves, digestion vessel and colorimeter is illustrated in Figure 3.

Figure 3: Hach EZ Process Analyzer.

TOC Monitoring

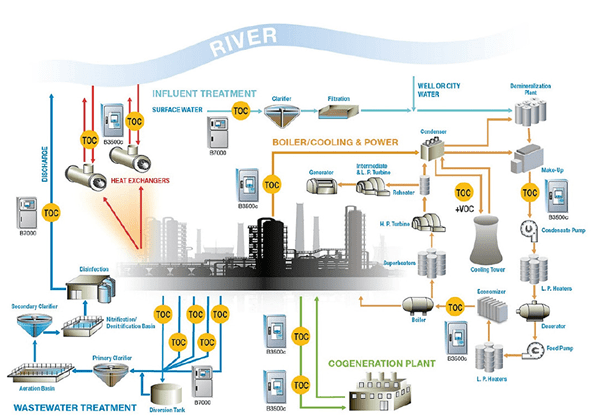

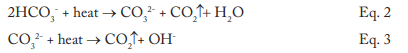

Another on-line monitoring parameter receiving increased and deserving attention is total organic carbon. As Figure 4 suggests, TOC data from numerous plant processes can be valuable.

Figure 4: Potential TOC sampling sites at an industrial facility (illustration courtesy of Hach).

Naturally, at plants such as refineries and petrochemical facilities, continuous TOC monitoring of condensate return and other process water streams can alert personnel to leaking heat exchangers and other equipment. For example, one of the authors relatively recently visited a liquefied natural gas (LNG) import facility that was being converted into an export facility. A major part of the process is removing hydrocarbons larger than methane from the incoming natural gas before liquefaction. The condensate return lines to the co-generation plant have TOC analyzers to detect organic contamination that might enter from this and other processes.

Consider some of the other sample points in this diagram. TOC could be a front-line indicator of potentially harmful organic compounds leaving the plant in a wastewater stream. If the plant has a non-fresh water source for plant makeup, such as reclaimed municipal wastewater effluent, TOC could again be a front-line indicator of upset conditions at the municipal wastewater plant. It is not unknown for plants that handle combined wastewater and storm runoff to be overwhelmed during heavy rains and need to bypass some wastewater that has received only primary treatment. Organic carbon levels can increase dramatically in these conditions. An increase in TOC to cooling tower makeup can upset cooling water chemistry, cause difficulties in high-purity makeup treatment systems, and, most importantly, influence microbial growth in heat exchangers, cooling tower fill, and other locations.

Conclusion

While various techniques are available for measuring trace level metals in process water, to date they have been rather unavailable to many industrial locations because of capital cost requirements or the need for specially trained technicians. This discussion outlined an existing technology that has been modified for on-line monitoring. This method is suitable for many facilities and can be operated by a wide range of plant personnel. Additional R&D continues exploring instrumentation for analyzing other metals of concern in wastewater processes. In many cases, these readings can be enhanced with TOC analyses to provide additional protection for industrial water/steam systems.

Of course, all systems are different, and, as with all other technologies, due diligence is necessary to determine the feasibility of utilizing such methods. Always consult your equipment manuals and guides.

References

[1] Post, R. M., Kalakodimi, R. P., Buecker, B., “An Evolution in Cooling Water Treatment”, PowerPlant Chemistry 2018, 20(6), 346.

[2] Rusyniak, D. E., Arroyo, A., Acciani, J., Froberg, B., Kao, L., and Furbee, B., “Heavy Metal Poisoning: Management of Intoxication and Antidotes”, Molecular, Clinical and Environmental Toxicology Volume 2: Clinical Toxicology (Ed.: A. Luch), 2010. Birkhäuser Verlag, Basel, Switzerland, 365.

[3] Giacoppo, S., Galuppo, M., Calabrò, R. S., D’Aleo, G., Marra, A., Sessa, E., Bua, D. G., Potortì, A. G., Dugo, G., Bramanti, P., Mazzon, E., “Heavy Metals and Neurodegenerative Diseases: An Observational Study”, Biological Trace Element Research 2014, 161(2), 151.

[4] Duffus, J. H., “Heavy Metals – A Meaningless Term?”, Pure and Applied Chemistry 2002, 74(5), 793.

[5] The CoMag System for Enhanced Primary and Tertiary Treatment, 2017. Evoqua Water Technologies LLC, Waukesha, WI, USA. Available from https://www.evoqua.com.

[6] Djukanovic, V., Buecker, B., Karlovich, D., “Coal-Fired O&M: A Novel Non-Biological Process for Selenium Removal”, Power Engineering International 2020. Available from https://www.powerengineeringint.com.

[7] Baird, C., Cann, M., Environmental Chemistry, 2012. W.H. Freeman and Company, New York, NY, USA, 5th Edition.

Authors

Brad Buecker (B.S., Chemistry, Iowa State University, Ames, IA, USA) is a senior technical publicist with ChemTreat. He has many years of experience in or affiliated with the power industry, much of it in steam generation chemistry, water treatment, air quality control, and results engineering positions with City Water, Light & Power (Springfield, IL, USA) and the Kansas City Power & Light Company’s (now Evergy) La Cygne, KS, USA, generating station. He also spent two years at a chemical manufacturing plant and an additional 11 years at two engineering firms. He is a member of the ACS, AIChE, ASME, AIST, AMPP (NACE), the Electric Utility Chemistry Workshop planning committee, and the Power-Gen International planning committee. Mr. Buecker has authored many articles and three books on power plant topics.

Ken Kuruc (B.S., Chemistry, John Carroll University, Cleveland, OH, USA) has been active in the power industry for over 25 years. In his current role, Ken provides technical support on all aspects of water quality monitoring for fossil power generation sites across the USA. He has co-authored articles which have appeared in various power industry publications and has presented at numerous utility and water chemistry conferences, including the International Water Conference, where he was awarded the 2019 Paul Cohen Award.

Contact us to learn more and request a consultation.

The post Monitoring Industrial Plant Discharge Metals and TOC appeared first on ChemTreat, Inc..

]]>The post Modern Techniques for Corrosion/Fouling Protection in Mid-Sized Cooling Towers appeared first on ChemTreat, Inc..

]]>Much has been written about protection against corrosion, deposition, and microbiological fouling in large power and industrial cooling towers and cooling water systems. However, the hundreds of thousands of moderately sized cooling water systems that supply other industrial and commercial facilities are sometimes overlooked. This article examines several key aspects for optimizing cooling system performance and reliability. Readers can find additional information by investigating the Cooling Technology Institute (www.cti.org), whose annual conference, committee meetings, and library are excellent resources.

Read the rest of the article online.

The post Modern Techniques for Corrosion/Fouling Protection in Mid-Sized Cooling Towers appeared first on ChemTreat, Inc..

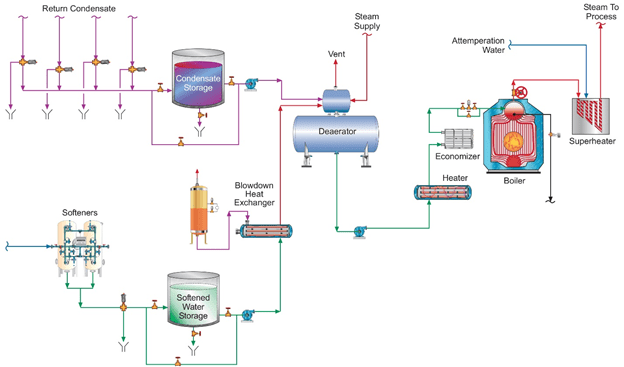

]]>The post Keys to Reliable Makeup Water Treatment for Boilers appeared first on ChemTreat, Inc..

]]>This article originally appeared in The Analyst, an AWT publication.

High-purity water is typically a must for power-producing steam generators, as the high-temperature/pressure conditions require control of impurities to low part-per-billion (ppb) concentrations to prevent serious corrosion and fouling. For the thousands upon thousands of low-pressure boilers at industrial plants around the country, however, water-purity requirements are usually not as stringent. Yet, incidents where poor design or failures in the makeup water treatment system have induced severe scaling and corrosion have been recorded for decades and continue to occur. These can lead to lost production and costly equipment repair or replacement. This article provides insight into the importance of makeup water treatment for low-pressure boilers and outlines modern technologies for producing good-quality makeup water at reasonable cost.

Low-Pressure Steam Generators

Low-pressure steam (pressures below 900 pounds per square inch gauge [psig] in general, and often between 50 and 600 psig) is used at many industrial plants around the country. For example, steam typically serves numerous processes at refineries, including as an integral heat source in atmospheric distillation, and in cracking and reforming processes. Steam feeds turbines for blast furnace air production at integrated steel mills; digesters and concentrators at paper mills; evaporators, crystallizers, and reaction vessels at chemical plants; and building heat systems everywhere. The list goes on and on.

The stimulus for this article comes from direct experience by the authors and too-frequent reports from our colleagues, who, upon entering plants for the first time find steam generators with serious scaling, corrosion, or steam purity issues that can be directly traced back to either poor design or inadequate attention to the makeup water system (and often condensate return chemistry). This frequently seems to occur as the result of plant management, operators, or technical staff focusing on process chemistry and engineering, with steam generation (and cooling water systems) appearing as rather nebulous entities that require less attention.

Most of the boilers in large industrial plants are the watertube style, frequently of the package type, although large boilers may be field-erected. Steaming rates (pounds per hour [lb/h]) are usually in the five to six-figure range. Commonly, these boilers include superheaters to raise the steam temperature above the saturation point and ensure the steam has the proper energy and/or remains dry until the point of use. For boilers that supply turbines, superheating is required to prevent excessive condensation in the turbine that could damage blades.

Makeup Treatment Issues

Probably from the time humans first began to heat water for personal needs, our species has observed deposition in heated vessels. These issues became much more acute following the invention and expanded use of the steam engine during the Industrial Revolution of the 18th and 19th centuries. The primary culprit was (and still often is) calcium carbonate deposition.

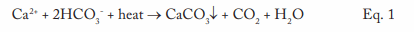

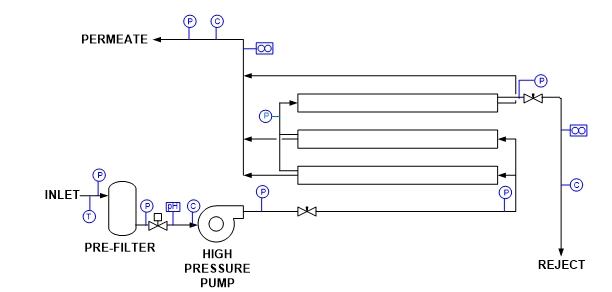

This equation outlines the reaction of calcium ions (Ca2+) and bicarbonate alkalinity (HCO3–) that can occur in hot water systems and boilers. A critical point to note is that CaCO3 is an inversely soluble salt, whose deposition potential increases with increasing temperature. As Figure 1 clearly illustrates, it is not a mechanism that has been relegated to the past.

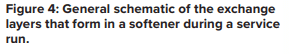

As steam generators increased in pressure and power in the last century, methods to minimize and control CaCO3 scaling became necessary. A common solution from the 1930s onward has been makeup water sodium zeolite softening, a technology that became practical with the development of synthetic ion exchange resins (Figure 2).

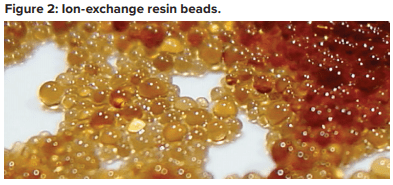

Each of these beads contains billions of active sites, which, for sodium softening, are typically sulfonic acid groups with sodium attached (SO3–Na+). Figure 3 illustrates a basic configuration of a softening vessel.

As makeup water passes through the vessel, calcium (Ca2+) and magnesium (Mg2+) exchange for sodium. The strongest affinity is for calcium followed by magnesium, so as a service run progresses, the resin develops stratified layers.

The softened stream, with hardness removed, still contains the other dissolved ions, including alkalinity, chloride (Cl–), sulfate (SO42-), and silica (SiO2). When the bed reaches exhaustion, it is regenerated with a brine solution that drives the hardness ions off into a waste stream, which is discarded.

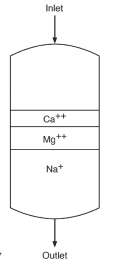

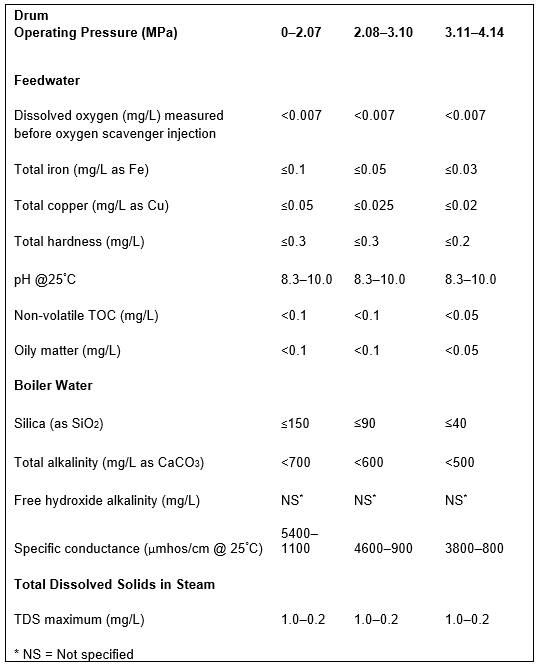

At this point, several features of sodium softening require some extra discussion. Many low-pressure steam-generating systems have been designed with sodium softening as the core boiler makeup treatment method, with no further treatment. And indeed, this may be sufficient for numerous steam generators. Table A outlines some general guidelines, extracted from a well-known American Society of Mechanical Engineers (ASME) source, regarding impurity limits in low- to medium-pressure watertube industrial boilers.

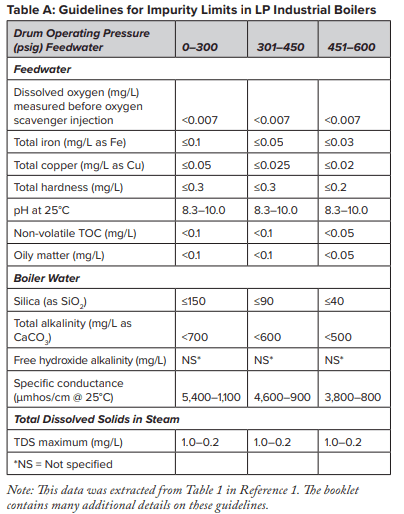

The data indicates that a significant amount of alkalinity can be tolerated in low-pressure boilers, and for many applications, some alkalinity may be desirable, as it helps protect metal surfaces from corrosion, a point we will return to later. However, HCO3, upon reaching the boiler, is in large measure converted to CO2 via the following reactions in Equations 2 through 4.

The conversion to carbon dioxide (CO2) from the combined reactions may reach 90%. CO2 flashes off with the steam, and when the CO2 re-dissolves in the condensate, it can increase the acidity of the condensate return.

Although the pH generated by this reaction has a relatively mild lower limit, the acidity is more than enough to cause significant carbon steel corrosion in condensate return systems. For example, 3 parts per million (ppm) of CO2 in pure steam condensate will lower the pH to 5.26. If dissolved oxygen is present in the system, corrosion can be greatly magnified.

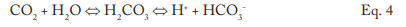

A unit operation that can minimize production of CO2 in the steam generator is illustrated in the following fundamental diagram.

Note the inclusion of a forced-draft decarbonator with acid injection to the feed. The acid conditioning forces Equation 4 to the left, and a well-designed decarbonator can reduce the CO2 concentration to a low parts-per-million (ppm) level. Caustic feed downstream of the decarbonator then raises the pH of the water to make it less corrosive on its path to the boiler. Note: If steam attemperation is provided by direct injection of feedwater from the deaerator, then caustic cannot be used to raise the pH. A nonvolatile compound (e.g., ammonia, an amine) is required.

Another issue briefly hinted at above now requires a bit of discussion. With too-frequent regularity, when technical representatives begin visiting a plant for the first time, they find boilers with scale deposition, corrosion, or both. In many cases, plant personnel will reveal softener problems that have led to hardness breakthroughs. Equation 1 and Figure 2 illustrate the potential effects of such difficulties. But even a softener/decarbonator operating properly still allows many ions, such as chloride and sulfate, to enter the boiler. Without close attention to boiler water chemistry and boiler blowdown control, the accumulation of these ions can cause corrosion and other problems, including foam formation in boiler drums. This in turn can lead to steam contamination and downstream issues. To re-emphasize, steam generator makeup system and boiler water chemistry control require just as much attention as process operations.

Something Better Than Softening?

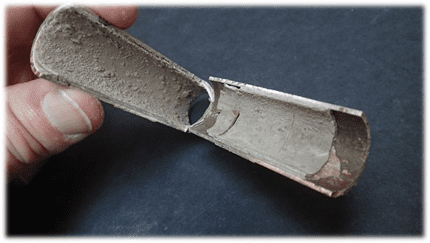

For modern makeup systems, reverse osmosis (RO) offers a reliable alternative to softening, where even basic systems can remove 99 plus percent of all ions from water. The osmosis process has been known for years. Two solutions of different concentrations, when separated by a semi-permeable membrane that only allows water to pass, will induce water in the dilute solution to move through the membrane to the other solution to balance the concentration. This phenomenon induces an osmotic pressure on the membrane until the solutions reach equilibrium. As the name reverse osmosis implies, the reaction is operated in reverse, and pressure produces purified water from a more concentrated stream.

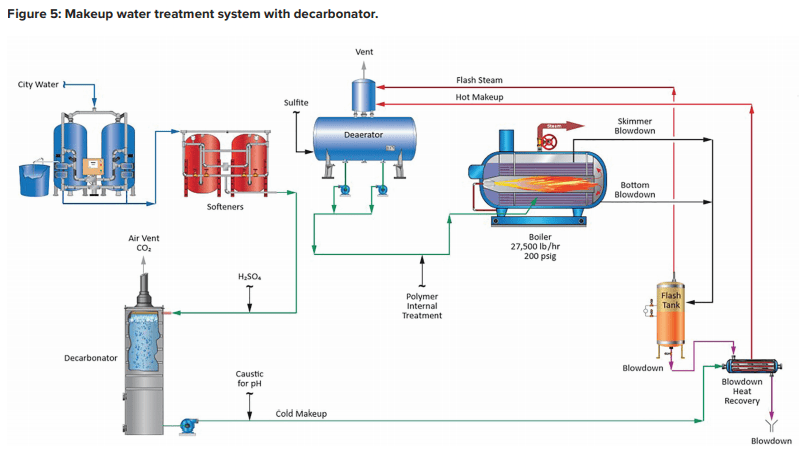

The potential application of RO as a makeup water treatment method became well known in the last century and became popular with the development of and improvements to spiral-wound membrane technology.

A flat membrane sheet has several layers as a backbone, which are all wrapped around a central, perforated plastic core. Feed enters the front end of each element and flows along the feedwater carrier while pressure pushes water through the membrane. The purified water, known as permeate, flows to the central core, and the increasingly concentrated feedwater (reject) exits the element.

Each RO pressure vessel typically has several elements arranged in a series.

O-rings seal each element along the walls of the pressure vessel so that the feedwater does not short-circuit any of the elements. A typical RO pressure vessel will have five or six elements.

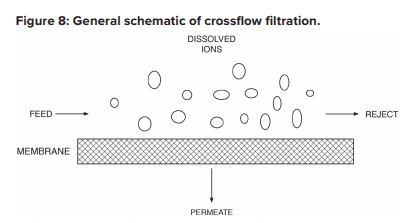

The configuration is designed to process the water via the mechanism known as crossflow filtration.

The feed flows parallel to the RO membranes, and pressure forces pure water through the membranes while the impurities are carried away with the reject. Only a few of the smaller monovalent ions (Na+, Cl-, silica, HCO3) pass through the membrane. However, while crossflow filtration is designed to keep impurities suspended in the reject stream, it is inevitable that even with exceptionally clean makeup, compounds will gradually build up on the membrane surfaces. Typically, residual suspended solids that are not captured by pretreatment will accumulate in the lead membranes of an RO system. Conversely, because dissolved ions concentrate as the water passes from one membrane to the next, scaling becomes an increasing concern in downstream elements.

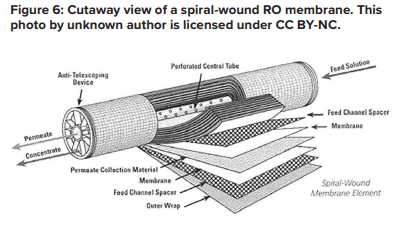

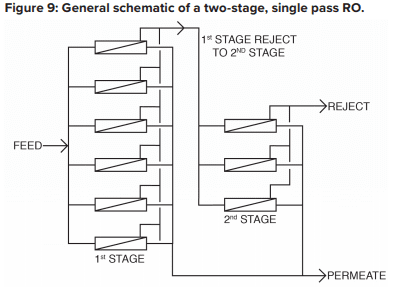

The basic RO system is a two-stage, single-pass type, as outlined in Figure 9.

A critical feature of RO is illustrated in this diagram. With “normal” feedwaters, approximately 50% of the feedwater is converted to permeate in each first-stage pressure vessel. This means that without further processing, 50% of the feedwater would be wasted. In the two-stage design shown above, the raw feedwater flows through six parallel pressure vessels in the first stage, and the reject from these vessels is routed through three additional pressure vessels in the second stage. Total water recovery increases to 75%.

For some applications, especially those for ultra high-purity water production, two-pass RO is common. In this configuration, the permeate from the first pass is treated in a separate set of membranes. Because the feedwater has already been significantly purified, 85% to 90% recovery from the second pass is achievable. The reject is recycled back to first pass inlet, and no water is discharged to waste from the second pass.

RO has become quite popular for several applications in recent years, especially for steam-based power generating units. RO plus polishing mixed-bed ion exchangers or electrodeionization can produce the high-purity water needed for steam generation

RO Fouling and Scale Control

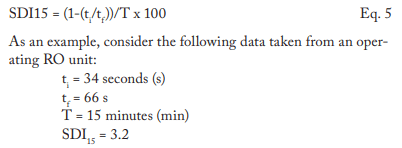

RO membranes, especially the lead elements, are susceptible to particulate fouling. An important measurement for determining this fouling potential is the silt density index (SDI). Usually, 5-micron (µm) depth filters are placed ahead of the RO to minimize the potential for particulate fouling. The SDI tests should be performed on the effluent from these filters. The SDI test is straightforward. A flowing sample of RO feedwater, downstream of the cartridge filters, is routed through a 0.45-µm filter at 30 psig pressure. Measurement is taken of the time for 500 milliliters (mL) of water to pass through the filter at the beginning of the test (ti) and again after 15 minutes (tf). The SDI is calculated as shown in Equation 5:

A general rule of thumb is that the SDI should be at least below 5 and preferably below 3. However, SDI should not be the only criteria that determines suitability of a RO application. The type of water and/or the nature of contaminants should also be considered. For example, in one application, the SDI readings of the RO feed always ranged between 1 and 3. Yet the membranes fouled with exceptionally fine iron oxide particles.

Scale formation is another issue that requires attention. When water flows through an RO pressure vessel, the concentrate continually accumulates dissolved solids, which increases the scaling potential. Calcium carbonate and sulfate can build up to a point where precipitation begins to occur. Other possible deposits include silica and alkaline metal silicates, strontium sulfate, barium sulfate, and calcium fluoride. While pretreatment can reduce the concentrations of many scale-forming compounds, the remainder may still cause problems. Barium and strontium sulfate scales are especially difficult to remove. Reputable membrane manufacturers have developed programs to calculate the solubility limits for these salts. The program will warn the user if any solubility limit is exceeded. The programs also provide “normalization” calculations of the RO system, as is described later.

Antiscalant feed is typical for RO systems. Common antiscalants include polyacrylates and phosphonates. The correct antiscalant or blend can control calcium sulfate at a factor of 7 above the saturation limit, strontium sulfate 800% above the saturation limit, and barium sulfate 6,000% above the saturation limit.

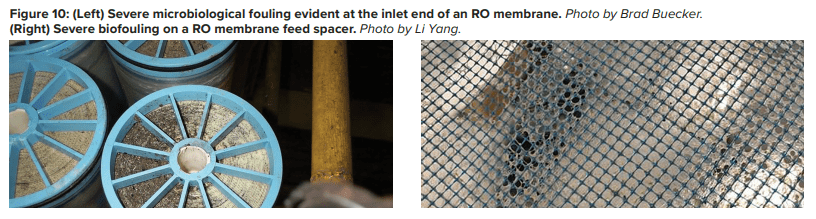

Pretreatment chemicals can affect membrane performance. Coagulating agents of the cationic variety and, most notably, aluminum compounds and some organic coagulants/flocculants, are particularly troublesome to RO membranes. If these agents are present, methods to remove them should be considered. Chlorine, usually introduced as bleach, injected into the primary plant makeup to control microbiological fouling will react with nitrogen atoms in RO membranes and irreversibly damage the materials. Chlorine should be removed upstream of the RO, but the absence of any biocides leaves the membranes in danger of microbial attack. Figure 10 shows how biofouling can damage a membrane element.

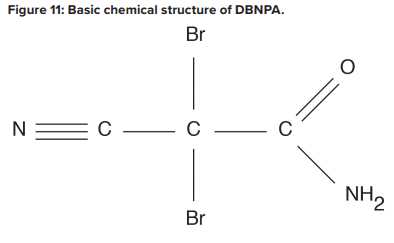

Biological fouling can cause irreversible damage to membranes because the deposits cannot be completely removed by standard cleaning methods. It is imperative to minimize conditions that can lead to microbiological deposition. Alternative techniques to chlorine are available to minimize microbe deposition within membranes. One is periodic treatment with a non- or mildly oxidizing biocide (frequency depends on fouling potential). A popular choice is dibromo-nitrilo-propionamide (DBNPA). A DBNPA chemical diagram is shown in Figure 11.

DBNPA is a fast-acting biocide that can be readily removed from any discharge by raising the pH to around 9, or commonly, treating with sodium bisulfite. Another possibility is a specialized version of chlorine dioxide (ClO2).A Such a product may sound surprising, as chlorine dioxide can act as a strong oxidizer in cooling water applications. However, in this case, the chlorine is not free, and thus does not react with nitrogen atoms in the membranes.

RO Cleaning

Even with well-controlled pretreatment and antiscalant chemistry, RO membranes will still collect deposits. The lead elements gather residual colloidal and suspended solids, while the downstream elements, especially those in the second stage, see higher concentrations of dissolved ions that may precipitate. Compounding the issue is that the pressure required to push water through the membranes can hold some of these particles in place. If impurities accumulate unchecked, the eventual result is irreversible membrane fouling.

Therefore, normalization programs are key for determining the need for and scheduling of RO cleanings. Temperature has a significant impact on permeate flux and pressure, and temperature changes can mask flow and pressure variations caused by suspended solids or scale buildup. Normalization programs use temperature, pressure, and flow measurements to provide corrected values for all temperature conditions. A common rule of thumb is to schedule a cleaning when the normalized value has dropped 10% to 15% from the baseline. Normalization programs can also help detect an increase in salt passage caused by a failed or degraded membrane, which might otherwise be attributed to temperature effects.

A two-step cleaning process is often employed to remove the potentially wide variety of foulants that can accumulate in RO membranes. Typically, in the first step, a high-pH (12 at 95°F) solution is circulated throughout the membranes. The alkaline solution removes organic compounds, microbiological and otherwise, that have accumulated. This stage is followed by a rinse and often a low-pH stage with citric acid as the key ingredient. Low pH helps remove soluble mineral salts such as calcium carbonate, while the citric acid will chelate metals, most notably iron. The inclusion of a heater in the cleaning loop can significantly speed up the process.

An important concept is to clean each stage separately. Otherwise, extracted impurities from one stage may foul the other, and vice versa. Also, cleaning systems are typically designed with cartridge filters in the cleaning loop to collect solids during the process. These filters should be replaced after each step in the cleaning.

The foregoing is general guidance only. Please consult your RO manufacturer for specific guidance.

RO Waste Stream Issues

As noted, a typical two-stage, single-pass RO system recovers approximately 75% of the inlet feed and produces a waste stream (reject) of the remaining 25%. This stream must be disposed somewhere. For plants with cooling towers, the basin of one of the towers is often an ideal location for the reject. Alternately, many plants have wastewater treatment facilities to condition discharge water before release to the environment. RO reject is basically plant makeup concentrated by a factor of four, so it should not overload the wastewater treatment equipment.

Makeup Water Treatment Issues Related to Boiler Water Treatment

A variety of treatment programs are available for low-pressure boilers, which may include phosphates, organic polymers, and sometimes chelating agents. These should be tailored to the chemistry of the water entering the boiler from both the makeup source and condensate return. A change from softened water to RO permeate can have a significant impact on boiler water treatment and even feedwater treatment. Higher purity waters are often known as “hungry” water because the lack of dissolved ions induces metals to give up ions to the water. Bicarbonate ions, even though they can react with calcium to form scale, will in many cases form a loose, protective layer on metals. For plant personnel considering a change from softened water to RO, these and other factors should be considered before making the switch. And, given that boilers should see a lower influx of hardness, the treatment program may need modification to account for this changed chemistry. A factor of major importance at many plants is the ratio of makeup water to condensate return. If the latter is much higher than the makeup flowrate, condensate return chemistry can dominate the selection of the best boiler water treatment program.

The post Keys to Reliable Makeup Water Treatment for Boilers appeared first on ChemTreat, Inc..

]]>The post Iron Monitoring in Industrial Steam Generating Systems appeared first on ChemTreat, Inc..

]]>By Frank Murphy, Ken Kuruc, and Brad Buecker

A previous issue of Water Technology outlined several important methods for improving water/steam chemistry in industrial steam generating networks to enhance equipment life and functionality.1 A partial extension of the earlier piece, this article shows how condensate and feedwater iron monitoring can alert operators and technical personnel to corrosion issues and can be used to optimize chemical treatment programs. For high-pressure steam generators that produce power and have high-purity makeup and feedwater, iron monitoring is valuable for evaluating a specific phenomenon: flow-accelerated corrosion.

You can read the rest of the article online here.

The post Iron Monitoring in Industrial Steam Generating Systems appeared first on ChemTreat, Inc..

]]>The post Take Better Care Of Your Low-Pressure Boiler appeared first on ChemTreat, Inc..

]]>By Brad Buecker and Chad Frierson

Many plants use low-pressure boilers to produce process steam for various applications, including heat for chemical reactors, evaporators, building spaces, etc. Often, sites pay less attention to the chemistry programs for these steam generators than to those for high-pressure units. Yet, contaminated condensate return, malfunctions of makeup water treatment systems, and other factors can cause many problems.

The post Take Better Care Of Your Low-Pressure Boiler appeared first on ChemTreat, Inc..

]]>The post The Challenges of Industrial Boiler Water Treatment appeared first on ChemTreat, Inc..

]]>This article was originally published in PPCHEM® Journal; PPCHEM® 2020, 22(6), 252–259; https://journal.ppchem.com/

Abstract

High-pressure steam generators for power production require high-purity makeup and feedwater and controlled boiler water chemistry to minimize corrosion and scale formation in the boilers, superheater/reheater circuits, and turbines. Numerous articles in the PPCHEM® journal over the last two decades have outlined these chemistries and their evolution.

However, while many heavy industries have high-pressure steam generators for co-generation needs, these plants and many other smaller facilities also have low-pressure boilers that produce process steam. The lower heat fluxes and pressures in these steam generators somewhat alleviate the stringent treatment requirements necessary for high-pressure units but offer more complexity in the choice of optimum treatment methods.

This article provides an overview of modern methods for protecting lower-pressure steam generators from factors that typically do not plague their high-pressure counterparts.

Introduction

High-pressure steam generators for power production require high-purity makeup and feedwater and controlled boiler water chemistry to minimize corrosion and scale formation in the boilers, superheater/reheater circuits, and turbines. However, while many heavy industries have high-pressure steam generators for co-generation needs, these plants and many other smaller facilities also have low-pressure boilers (boilers of less than 4.14MPa (600psig)) that produce process steam. The lower heat fluxes and pressures in these steam generators somewhat alleviate the stringent treatment requirements necessary for high-pressure units but offer more complexity in the choice of optimum treatment methods. Potential issues such as contaminated condensate return and makeup water treatment system malfunctions can increase the complexity of steam generation water/steam treatment.

This article provides an overview of modern methods for protecting lower-pressure steam generators from factors that typically do not plague their high-pressure counterparts.

The Complexities of Makeup, Condensate Return, and Feedwater Chemistry

In utility systems, the steam is condensed and returned to the boiler after performing its work in the turbine. The complete water/steam circuit is nearly a closed loop with approximately 0.5–2% water loss and corresponding makeup additions. Mature technologies such as reverse osmosis (RO) and ion exchange are available to produce high-purity makeup (≤2μg∙L–1 of sodium and chloride, ≤10μg∙L–1 of silica, and ≤0.1μS∙cm–1 specific conductivity). In the absence of a condenser tube leak or, less frequently, makeup system upset, the feedwater remains highly pure on its path to and through the steam generator and turbine, and for that small portion utilized for steam attemperation.

Now consider the realm of low-pressure steam generation, where the boilers do not require demineralized makeup. For decades, and even today, sodium zeolite softening has been a common primary treatment method for industrial boiler makeup. In this process, the makeup passes through a bed of ion exchange resin that trades calcium and magnesium hardness ions for sodium. The softened stream, with the remaining impurities including bicarbonate alkalinity (HCO3–), chloride (Cl–), sulfate (SO42–), silica (SiO2), and others, then feeds the boiler. Some softening makeup systems include a splitstream de-alkalizer, or perhaps a forced-draft decarbonator, to remove most of the alkalinity. This can be beneficial, as will be outlined.

Basic softening offers both advantages and drawbacks. Compared to complete demineralization, softening saves plants money in equipment and operating costs. Regenerating softening resins with brine is straightforward and does not require storing and handling dangerous acids and caustic. The major difficulty with softening is that the ions not removed by the process can become problematic upon reaching the steam generator. Alkalinity is a prime example. If it is not removed from the makeup, alkalinity will at least partially convert to carbon dioxide (CO2) in the boiler, carrying over with the steam. Upon steam condensation, the CO2 can lower the pH, leading to potential condensate corrosion issues for carbon steel piping.

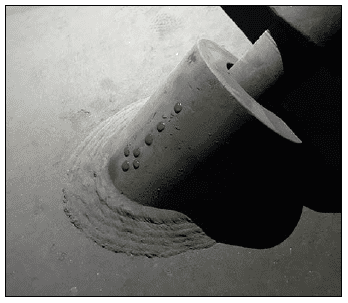

The introduction of other water impurities to the boiler can lead to higher conductivity, increasing the general corrosion potential of the water, especially because the ions “cycle up” in drum boilers as steam is produced. While some accumulation of these impurities is tolerable, in many cases, plant personnel do not track deposit buildup in boilers, particularly of iron oxide corrosion products transported from elsewhere, e.g., condensate return systems. Boiler water impurities can concentrate under these deposits to much higher levels than in the bulk water, and induce under-deposit corrosion.

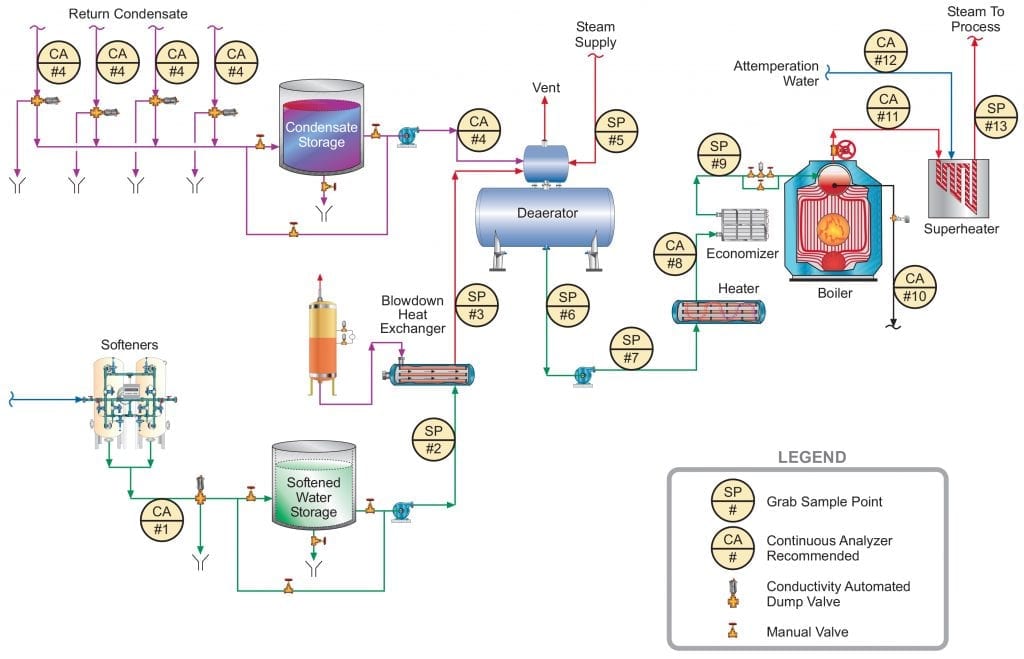

Heavy deposits also restrict heat transfer, and in areas of high heat flux may lead to tube overheating and mechanical failure as shown in Figure 1, where iron oxides from condensate return created thick deposit layers followed by fishmouth opening of the tube from overheating [1].

RO technology offers a reliable option for producing makeup water with very low dissolved solids. At many power plants, RO serves as the primary demineralization step with mixed-bed ion exchange or continuous electrodeionization (CEDI) polishing as the final stage, but RO as a stand-alone process can suffice for many low-pressure boilers. The process removes the bulk of impurities (often 99% or more), including silica, which can allow for higher boiler water cycles of concentration, thus saving costs via reduced makeup and blowdown.

Sufficient pretreatment to remove suspended solids ahead of RO membranes and a well-designed chemical treatment program to minimize scale formation are important to successful RO unit operation. Careful RO feedwater analysis is critical for proper pretreatment equipment and chemical selection. Also, RO generates a nearsteady wastewater stream that must be disposed of. For plants with cooling towers, the tower basin may serve as a good repository. Otherwise, alternative disposal methods may be needed.

There are many examples of makeup system upsets wherein plant personnel operated the systems in failed mode or sometimes even bypassed malfunctioning systems and fed raw water to the boiler. A mindset of “water is water” seems to prevail in these cases. Such assumptions can lead to disastrous consequences, and boiler tubes have been known to fail within days or sometimes hours of such decisions.

Feedwater and Condensate Return Issues

Apart from whatever method is utilized for makeup water production, significant impurities can enter the steam generator via condensate return from plant processes. The percent condensate return may range from slight to very large depending on plant design and operation. In a classic example of contaminated condensate observed years ago by one of the authors, superheater bundle replacement of four package steam boilers at an organic chemicals plant was required every 1.5–2 years because of internal deposition and overheating failures. The root cause was excessive organic ingress to the condensate return, which induced foaming in the boiler drums and solids carryover to the superheaters. No systems were in place either to polish the condensate or to dump it during impurity excursions.

Depending on the chemical processes at the plant and the ability of impurities to enter the condensate, a wide variety of contaminants can potentially enter the boiler. A program should be in place to detect chemical leakage from heat exchangers, reactors, or other vessels, and to make repairs as needed. Testing condensate return for pH, hardness, and specific conductivity is common. And, it might be prudent to check the return condensate for organics in specific cases. With such monitoring, the condensate can be diverted to drain if the measurement exceeds a predetermined limit, e.g., 50μS∙cm–1 continuous on-line conductivity. Setpoints for dump or reuse of return condensate should be defined for all site-specific parameters that might impact boiler feedwater quality. Condensate dumping can be expensive considering the costs for makeup water production and heating water to produce steam; however, plant personnel may rely too much on the boiler water treatment program to alleviate problems. Excessive contamination can overload any treatment program.

As with high-pressure steam generators, establishing and maintaining a moderately basic pH range (in general, pH 9–10) is an important issue for feedwater and condensate return systems in low-pressure units to prevent general carbon steel corrosion. In the power industry, the common pH conditioner is ammonia, which raises feedwater pH via the following reaction:

This is a reversible reaction, so the alkalinity increase is limited, which usually minimizes excessive steel corrosion in the event of a chemical feed upset. (High ammonia concentrations, especially in the presence of oxygen, can be very detrimental to copper alloys.) Conditions are often different in low-pressure boilers. If the makeup water is sodium-softened only, sufficient alkalinity may be present to maintain a basic pH. Sometimes a bit of caustic feed may be employed to boost feedwater pH, although care must be taken when using this strong chemical.

However, the wild card for industrial systems is condensate return, in which the pH may be significantly depressed by carbon dioxide carryover. Accordingly, neutralizing amine injection to condensate return is often employed to minimize corrosion in carbon steel piping networks.

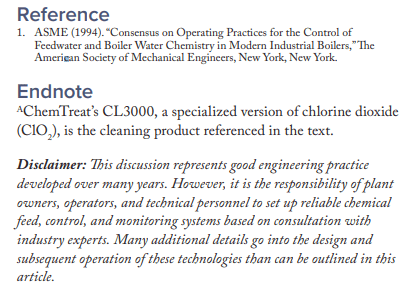

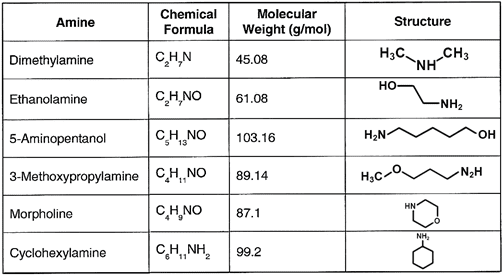

A common injection point is the storage section of the deaerator or directly to the steam header, which may be better. The chemical or chemical blend not only protects the condensate but carries through the system. Table 1 details several of the most common neutralizing amines.

Table 1: List of common neutralizing amines.

The amines all have a higher molecular weight than ammonia, and thus will not flash off as readily, although each has its own distribution ratio (the amount remaining in the water vs. that departing with steam) whose properties are a function of temperature and pressure. The products also have different basicities, providing flexibility in treatment program selection. Careful evaluation of condensate return system operating and design conditions is necessary to select the most appropriate amine or amine blend.

Some compounds are not allowed if the steam can directly contact food or other consumable products.

As discussed in a previous issue of the PPCHEM® journal, monitoring total iron concentrations in condensate is highly recommended to evaluate feedwater chemistry efficacy [2]. We will return to this idea again later in this article.

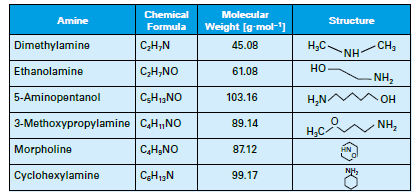

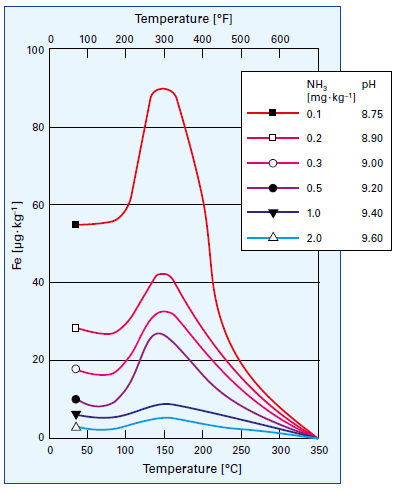

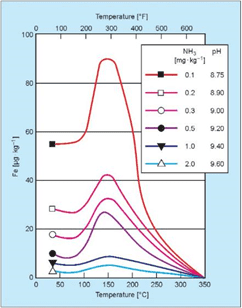

Dissolved Oxygen Control

In the middle of the last century, the consensus about dissolved oxygen (DO) in boiler feedwater was uniform: oxygen should be eliminated because it is highly corrosive. But European and Russian researchers in the late 60s and early 70s discovered that some dissolved oxygen (at concentrations up to 300μg·L–1) introduced to high-purity water during normal operation induced formation of a tight α-hematite oxide layer on carbon steel piping. Corresponding particulate and dissolved feedwater iron concentrations could be driven to very low values of 1μg·L–1 or even less. The program became known as oxygenated treatment (OT) and was widely applied to once-through supercritical units in Europe and, eventually, in the United States and elsewhere. The caveat for OT is that it requires exceptionally high-purity feedwater (≤0.15μg·L–1 cation conductivity); otherwise, oxygen corrosion may occur. Figure 2 illustrates this concept.

Figure 2: Oxygen corrosion rates as a function of dissolved solids content. [3]